TrackTreads

The cost risk of falling behind.

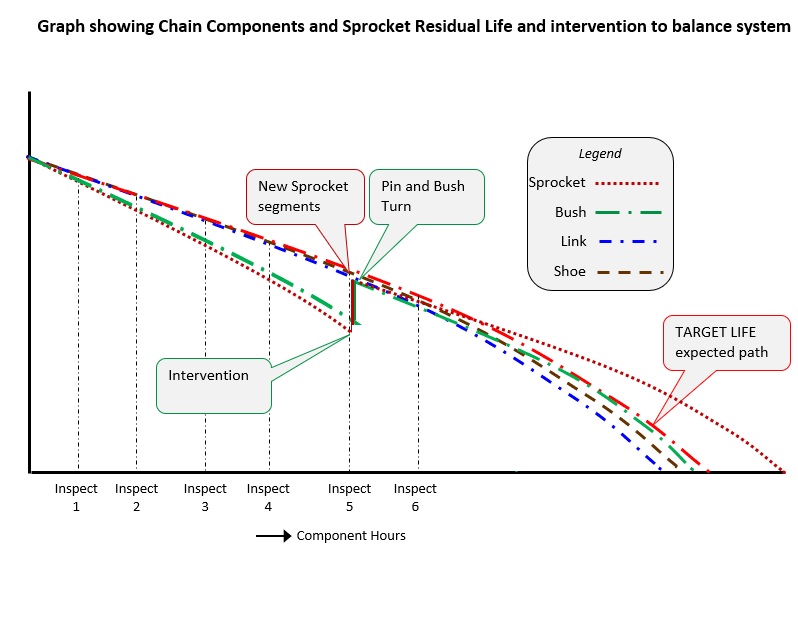

Undercarriage inspections are the norm whether for a mine-site, construction fleet or in Sales and Service of Undercarriage components Mine-sites use the inspection data to plan their maintenance on the tracked machines and monitor their cost per hour Construction-Fleets use the inspections to monitor the condition of their fleet and Read more…