TrackTreads

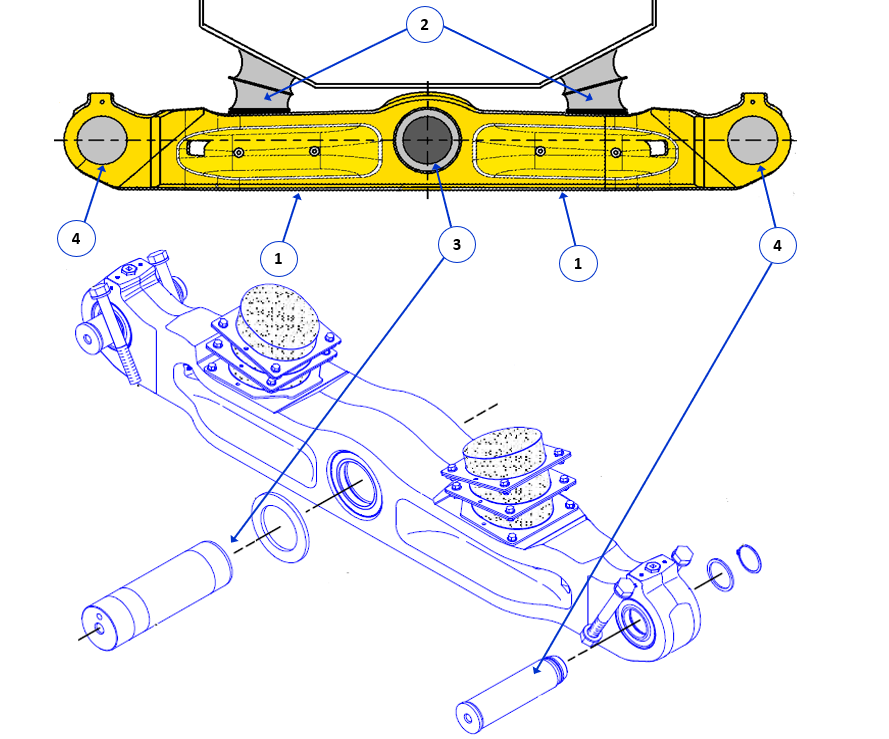

Avoid Spending Big on Bogies by Inspecting the Bogie Hardware as part of the Undercarriage Inspection

Major Bogies carry the load of the machine on the rails (Links) and any miss-alignment, wear or damage can create large costs. Identifying problems on bogie components before they fail can reduce this cost significantly. Regular inspection should be completed, and what better way than to include it within the Read more…