Software is just another tool you need in your toolkit in order to manage and repair your undercarriage components. It is no different to sending your car to the dealer for a service, and the service technician plugs his highly specialised software diagnostic tool into your car to determine the health of the engine and surrounding components. Undercarriage Inspection Management Software is no different, collecting inspection data to determine the health of the components and then providing a list of repair or replacement actions to be completed.

The car dealer principal would not think twice about purchasing the Highly Specialised Diagnostic Software Tool to enable his technician to perform his task effectively. Diagnosing Undercarriage Condition is no different. However, many companies still try to manage their undercarriage without the enabling tools.

The decision to spend on Undercarriage Management Software will be insignificant after calculating and taking into consideration the savings to be achieved by managing some of the following areas of Undercarriage costs.

- Changing out undercarriage components too early – lost value

Inspecting Undercarriage Components regularly ensures that components are changed out as close to 100% as possible. Components replaced at a point in their life any earlier than 100% are money lost. Let us take an example. A D11T undercarriage costing $100,000 per side would be expected to last 6,000 hours. Should this chain be changed out at say 90% worn, 10% of its value, representing $10,000 is lost. The undercarriage will only achieve a possible ef

e tools in the company toolkit.

- Matching life of components in system

Matching of components to achieve the maximum life of the entire system avoids loss of value where components do not achieve the 100% worn target. This is a balancing act requiring assessment of

- Cost of stopping the machine in terms of lost production

- Cost of the repair

- Cost of lost value if the component is not replaced and thus does not achieve 100% worn.

Each scenario needs to be considered by the planners in order to make the correct calculation and then decide which route to follow. Without the software, and regular inspections, this will not be possible.

- Reducing amount of maintenance stops for repairs

Each time the machine is stopped for maintenance, it results in lost production time along with extra costs associated with maintenance. Maintenance items need to be identified and then scheduled so that the asset is achieving maximum return.

- Reduced life caused by operator skill levels or unresolved inspection issues

In our example of the D11T above, the budget life expected on the undercarriage is 6,000 hours. Giving a cost per hour of $200,000 X 2 Sides / 6,000 hours = $33.33$ per hour if this life is achieved. If the life achieved is any less than 6,000, say for argument sake 5,400 hours is achieved, the cost per hour is then $37.03 per hour, equalling an 11% increase in cost per hour. This however does not include removal and freight costs for unscheduled maintenance.

Operators can impact the life of the undercarriage and inspectors should be aware of the signs of operator skill in order to correct such skills issues. Examples would be

- Dozing uphill

- Turning predominantly in one direction

- High speed Reversing etc

The TrackTreads help centre has an exhaustive list of observations to assist operators.

Issues having been observed at inspection need to be corrected in order to slow or stop the accelerated wear. A prime example would be a tight chain.

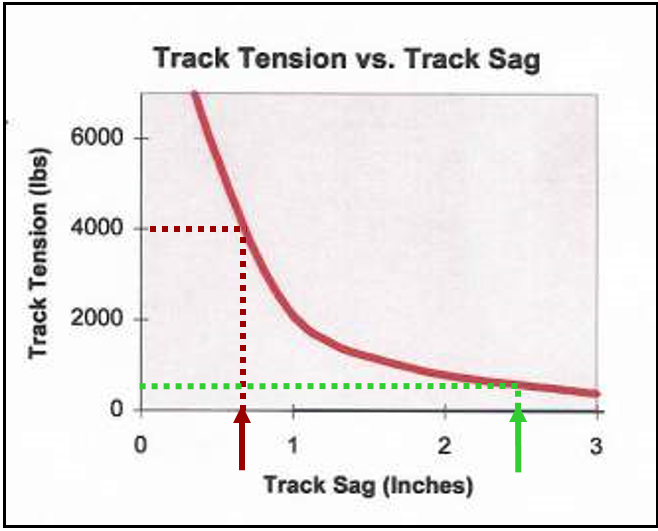

The D8T W/Carrier roller has an ideal track sag of 2.6”. With only a 2” reduction in track sag, you get over 4 times the chain tension, resulting in 4 times the wear. The increased wear isn’t just limited to the chain, the tension will impact on all undercarriage components, and reduced drawbar pull as a result of extreme forces will then burden the drive train. Just 2” on the chain will be costing you money.

So Is Undercarriage Management Software actually expensive? The simple answer is no. Not only is it not expensive, when used properly by smart asset managers, undercarriage management software is a time and money saving investment.

If you’re a smart asset manager and you’d like more information, or to see a demo of the TrackTreads system in action, contact us at: information@tracktreads.com

0 Comments