Major Bogies carry the load of the machine on the rails (Links) and any miss-alignment, wear or damage can create large costs. Identifying problems on bogie components before they fail can reduce this cost significantly. Regular inspection should be completed, and what better way than to include it within the undercarriage inspection. Inspection points to be included in the Other Observations in the Undercarriage inspection are:-

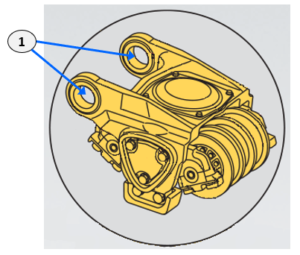

- Check for signs of wear and oil leaks in the Major Bogie pin and seals (Note: avoid major damage pin wear as this can lead damage of the bogie frame which then becomes a lot more expensive to repair and rebuild)

2. Check the condition and wear of the Bogie pads both top and bottom

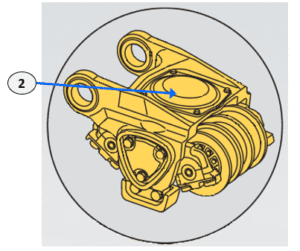

3. Check that all Hardware bolts are present and tight

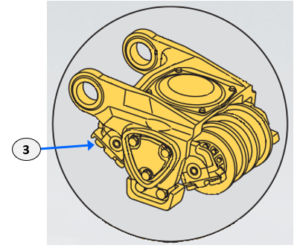

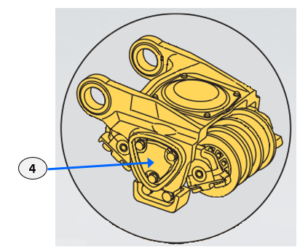

4. Check the condition of the minor bogie pin and seals (Note: at 4000 hour intervals, remove the cap and test the oil levels and pressure cording to the standard procedures)

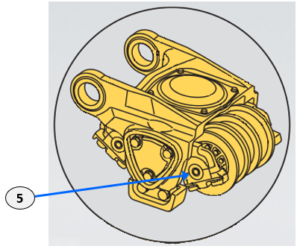

5. Check that end caps are present

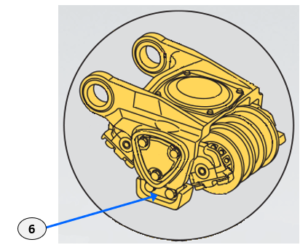

6. Check that the Chain Guides are in place with all hardware secure and also check the level of wear

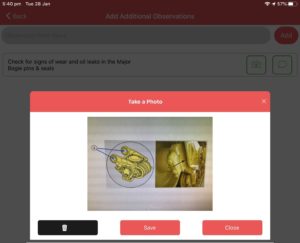

TrackTreads Undercarriage Inspection Technology ensures these points are observed at the inspection

The TrackTreads system enables Inspection Lists of other observations to be created and included at all inspections.

- This ensures no observation points are missed,

- Images and comments can be included for later reference

- An Inspection history is built for each point – Audit Trail

- Any potential problems are identified and can be reviewed later

Every Undercarriage Inspector looking for repair opportunities should be examining the bogies and their related hardware

To get further information and arrange a free demonstration simply fill in the form below.

[contact-form-7 id=”2772″]