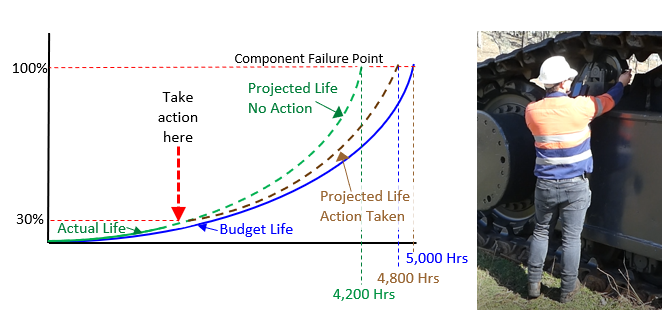

The Undercarriage Components installed on your equipment are expected to achieve a certain budgeted life. However, this is not where the story ends, because the components will not achieve their budgeted life if they are not properly managed, and the only way to manage undercarriage components is to measure them.

Early identification of issues causing accelerated wear and prompt restorative actions enable you to achieve as close to budgeted life as possible.

Measuring the components will identify and highlight early warning signs of increased wear rates. Wear rates can be increased by a number of causes, including;

- Underfoot Conditions

- Track tension

- Operator Techniques

- Increased wear on some components causeing others to wear

- machine balance

- …and many more

These are all indicators to be aware of when performing an inspection on the undercarriage. The main aim of which is to achieve the budgeted life on the components, and where components are showing signs of premature wear, corrective actions can be taken. There is a huge amount of money in your undercarriage and without management, that money can be wasted.

To get further information and arrange a free demontration simply fill in the form below.

[contact-form-7 id=”2772″]