Images snapped in the field during an inspection to illustrate an issue identified creates a richer view of the problem and will often replace a thousand-word description of the problem. This saves enormous amounts of time which is money!

Images speed up the inspection process because they save having to describe the issue in words – Most importantly and image or 2 provides a better description than the image that can be described in a thousand words. Writing a thousand words also takes long especially on a mobile device keyboard or through dictation

A fault can be recorded in the field on one side of the world and then passed onto an expert for analysis on the other side of the world – this creates the picture for detailed analysis without the expert needing to be onsite and in the field, often at large cost.

It can be used as reference material in historical inspections – images taken of a particular component or issue across several inspections over time provide a history which can be reviewed. A good example is a crack in a frame which needs to be measured and tracked over time until repairs can be completed

It can form the basis of a Work order to illustrate to the service Technicians what needs to be fixed – an image with and instruction to repair makes it a lot easier for a service technician to complete the repairs as required

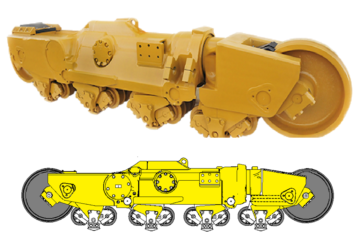

On Component Rebuilds, a timeline of images can tell the complete story of the rebuild – a timeline of images from the used cleaned component prior to repairs with measurements and cracks gouged, through the entire repair and rebuild process builds a solid record of the rebuild in all its detail that can be viewed to ensure rebuild integrity.

TrackTreads Digital Field Inspections allow any number of images to be recorded against each observation point to avoid the thousand-word description.

0 Comments