Uncategorized

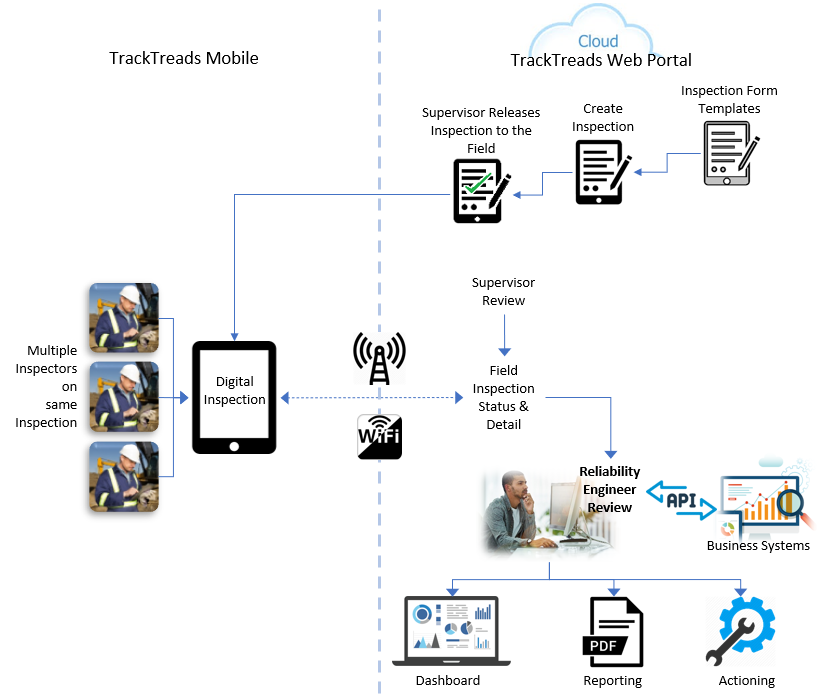

Where does the advantage lie in Digitizing Undercarriage Inspections

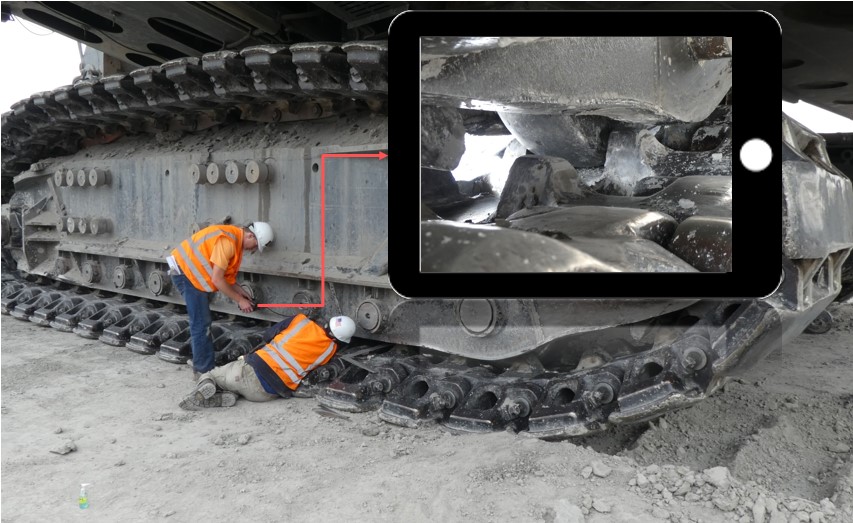

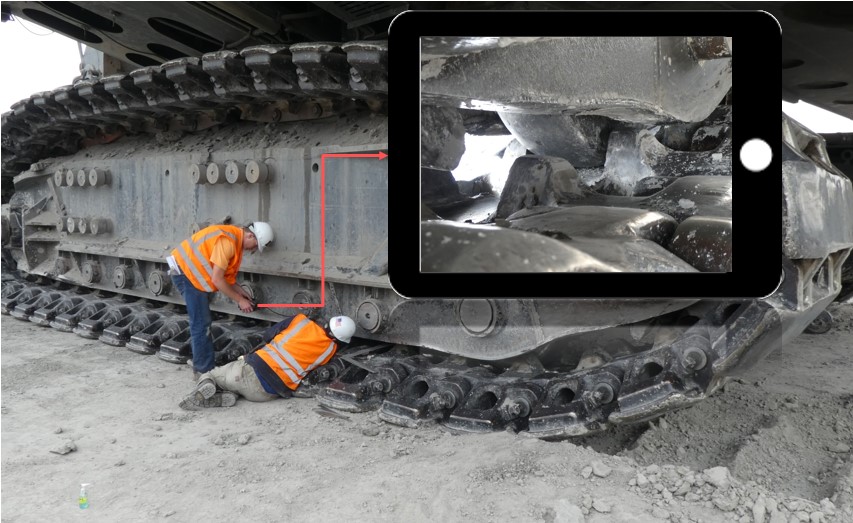

The time taken to complete a full Undercarriage inspection manually on a dozer is on average about 20 to 25 minutes covering both sides. A field Rope Shovel inspection on the other hand can take between 2 and 4 hours depending on the number of inspection or observation points and how much cleaning needs to be done. The length of the inspection will normally determine the volume of data that is captured, especially images. Rope Read more…