Mining Shovels are high impact machines, not just in relation to the work they do, but also by virtue of the impact they can have on your production timeline and your bottom line. For this reason, undercarriage management on these machines is particularly important.

It is critical that you select, monitor and manage the correct undercarriage components effectively to avoid machine failures and the inevitable flow on expenses of these failures. Mining Shovels are critical production machines and downtime needs to be planned and managed carefully to minimize lost production. Unplanned downtime means not only lost production revenue, but a fleet of trucks and other support equipment can be left at a standstill, while drivers and operators still have to be paid.

Comprehensive monitoring of undercarriage components enables you to better plan for component replacement downtime. You can be sure the correct inventory is held, and that the correct tooling and labour resources are available when required. This type of planning and preparation is only possible with regular undercarriage inspections.

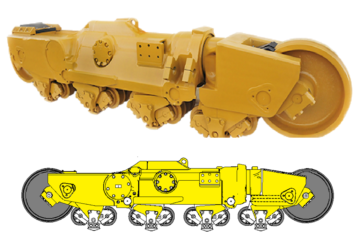

Undercarriage components on Mining Shovels can be more complex than conventional tracked machines. Some of the components will have multiple measurement points to determine how worn they are. For example, a Sprocket requires at least 2 measurements, and these measurements cannot be simply done with a tape measure. Accuracy of these measurements is also paramount to ensure correct evaluation of wear percentages and the subsequent forecasting of residual life.

TrackTreads is a strategic undercarriage consulting service provider as well as a software and support provider of undercarriage management software. Our software enables you to achieve maximum availability and optimal life from your crawler undercarriage. This is achieved through:-

- A customized mobile device application for inspections. This application records measurements, comments and images, whilst simultaneously calculating wear percentages. This allows inspectors to review accuracy and correctness of the measurements in real time.

- A comprehensive database of component measurement methods and wear rate values and calculations. Components all have their own wear measurement methods, along with distinct wear percentage values and evaluation codes, our application contains these values and codes and automatically calculates wear percentages from the individual system limits.

- A help centre that provides detailed “How to Measure” videos that assist inspectors with using the applicable measurement method for the component being measured.

- Residual life calculations for each component. This allows you to more accurately predict when components will need replacing, and from this, plan your replacement schedule. You can schedule multiple components in a system for replacement, using your preferred balance of early replacement when a component has remaining life and the downtime required for replacements.

- An archive of unusual wear patterns and premature failures of undercarriage components. This archive provides detailed descriptions and images along with possible causes and recommendations for improving undercarriage life and durability.

- A software system that caters for all OEM’s along with all models of mining shovels. This can be of great value when you are operating mixed fleets, but want to manage all undercarriage in a single system.

- A complete inspection tool kit equipped for measuring all components on the mining shovels.

To request a demonstration of how the TrackTreads software can benefit you, Contact Us

0 Comments