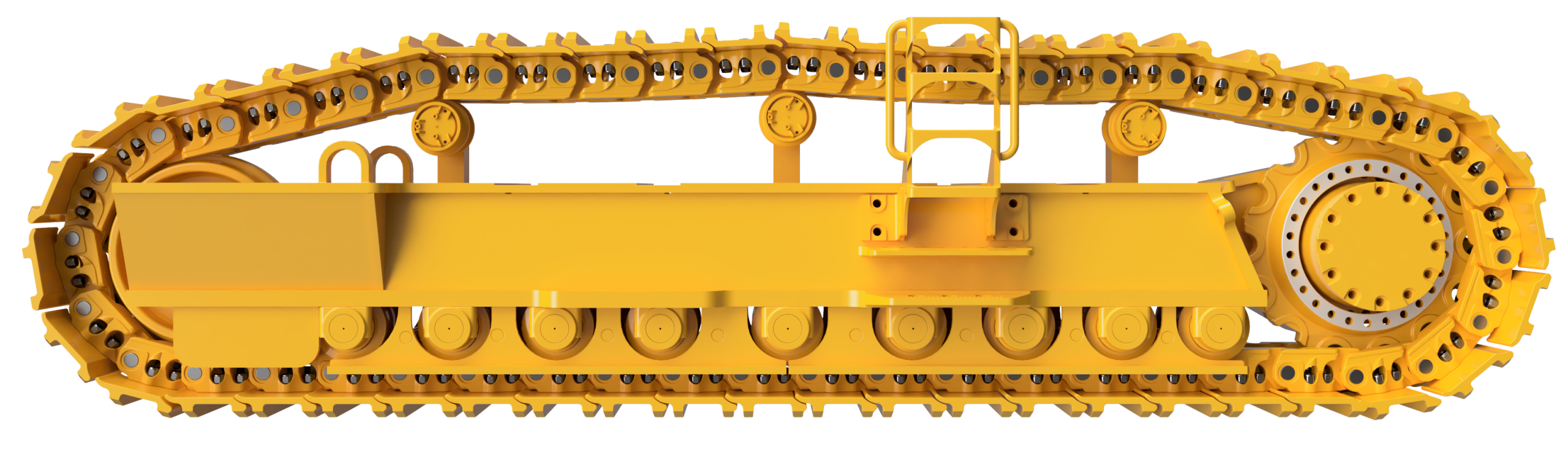

Undercarriage

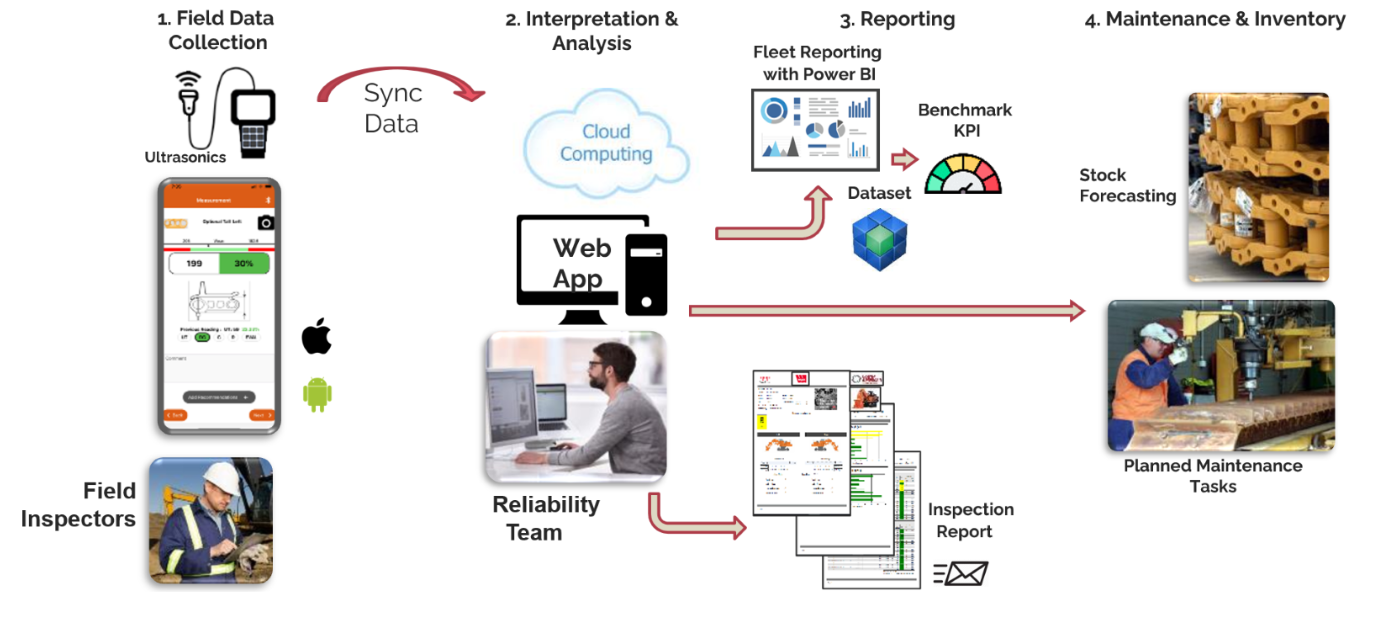

End to End Undercarriage Management

TrackTreads is a complete software solution for managing a machines undercarriage. It provides a repository of your undercarriage inspection data, an inventory management system to ensure you are always ready when replacements are due, a scheduling system to ensure your machines are inspected when due, enables you to analyse component life performance and compare various makes, a full help centre with training material and videos for using both the software and general undercarriage advice, and so much more!

End to End Undercarriage Managements

TrackTreads delivers a powerful toolkit of intelligent software, precision measuring tools, and advanced data analytics—empowering you to achieve component life, control maintenance costs, and maximise your return on investment.

Accurate, real-time inspection data is captured directly in the field using our mobile app — available on both Android and Apple devices. This ensures every measurement, image, and observation is consistent and reliable, forming the foundation of informed decision-making.

Our team of experienced Reliability Engineers interprets the collected data by comparing it with historical records and trend patterns. This expert analysis determines current component health and identifies the right maintenance actions — with precise timing — to optimise equipment performance and longevity.

We deliver actionable insights at both operational and strategic levels through two powerful reporting formats:

- Inspection Report – A detailed, machine-level report that includes:

- Component % worn

- Total hours and distance travelled

- Estimated remaining service life

- High-resolution images for visual context

Each report builds a complete narrative, supporting maintenance planning and compliance.

- Fleet Power BI Dashboard – A live, interactive dashboard offering comprehensive visibility across the fleet with insights grouped into four key focus areas:

- Current Fleet Condition – Real-time health status of all undercarriage components

- Outstanding Maintenance Tasks – Machine-specific maintenance priorities, ranked by urgency

- Historical Performance – Tracks component life at removal (% worn, hours, distance), benchmarked for performance analysis

- Future UC Plan – A 6–12 month predictive maintenance roadmap, outlining component replacements, hour meter targets, scheduled dates, and estimated costs — perfect for budgeting, procurement, and inventory planning

Once maintenance is scheduled, all tasks are executed and recorded within the system. Replacement parts and components are ordered, tracked, and managed, ensuring full inventory visibility and alignment with upcoming service needs.

Field inspection - Precision Wear Measurement in the Field that Drives Smarter Decisions

Accurate measurement and consistent data capture are the foundation of effective undercarriage management. Our system is designed to identify wear trends early, detect risks, and drive smarter maintenance decisions.

Precision Measurement & Wear Analysis

Capture component measurements with high accuracy and consistency—ensuring even subtle signs of accelerated wear are detected early.

Comprehensive Inspection Records

Each inspection includes a full set of data: Accurate measurements High-resolution images Detailed technician observations Together, these records create a complete picture of component condition at every service interval.

OEM-Specified Wear Calculations

All measurements are automatically converted into % worn values using OEM standards—providing a consistent and objective basis for fleet-wide comparison.

Automated Validation & Accelerated Wear Detection

Built-in validation logic flags anomalies by comparing each new inspection against: OEM wear limits Historical inspection results Expected wear rate trends This automation helps Reliability Engineers identify accelerated wear early before it results in unexpected failures or costly downtime.

Data-Driven Reliability Insights

All collected data contributes to a complete wear history. This empowers your team to: Plan proactive, targeted maintenance Extend component life Optimise reliability strategies across the fleet

Interpretations - Transform Field Inspection Data into Actionable Intelligence

Unlock the full value of your inspection data with our powerful web-based analysis and reporting platform. Designed for efficiency, collaboration, and insight, this facility empowers your team to make fast, informed maintenance decisions—no matter where they are.

See the Story Behind the Steel

Access inspection results, images, and expert comments—every mark, measurement, and wear point tells a story.

Compare with Historical Trends

Instantly benchmark current conditions against past performance to detect anomalies and trends.

Spot Issues Before They Escalate

Identify components showing signs of accelerated wear and determine the exact maintenance action needed.

Maximise Component Life Through Smart Planning

Schedule replacements at the optimal time to extend system life and avoid premature costs.

Generate Clear, Actionable PDF Reports

Summarise findings in a professional, shareable format to keep stakeholders informed and aligned.

Seamlessly Trigger Work Orders

Raise work orders directly to your in-house system via powerful API integrations—no double-handling, no delay.

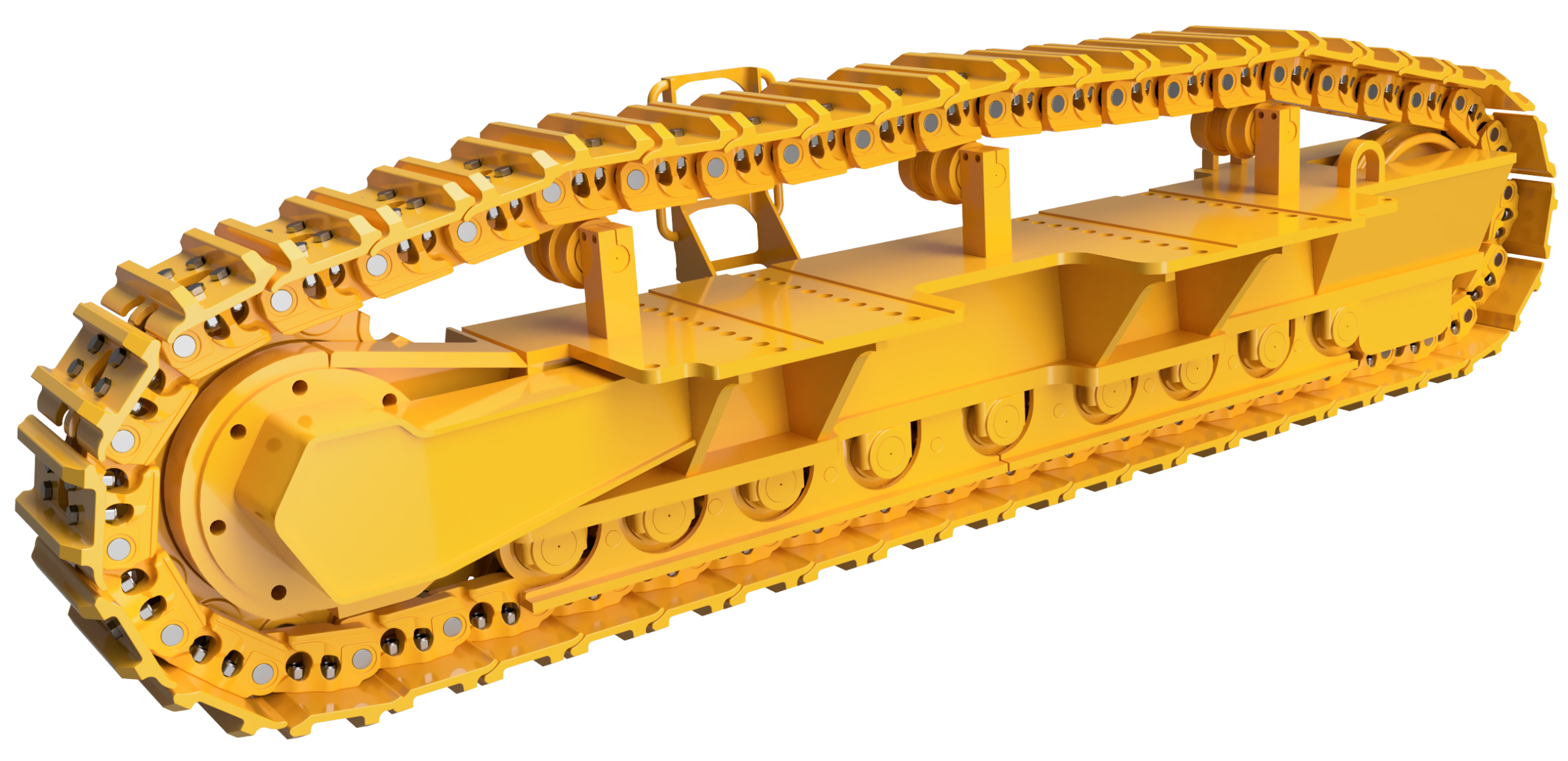

Inventory - Full Visibility and Accountability of Swing Chains and Frames

Efficient inventory management is critical to ensuring the performance, reliability, and lifecycle optimisation of Swing Chains and Frames on the Tracked Equipment to ensure maximum uptime. Our system delivers complete transparency and control—supporting operational readiness, cost management, and smarter decision-making.

Maintain comprehensive inventory control with accurate, real-time records of all Swing Chains and Frames—whether in use, under repair, or in stock. Essential inspection data is captured for every component, including measurements, condition assessments, technician comments, and high-resolution images. Each Chain and Frame is assigned a unique serial number for traceability across usage history, location, and current condition. Track operating hours and distance traveled to assess wear, forecast replacements, and extend service life. All repairs, rebuilds, and replacements are logged to build a complete lifecycle history, supporting reliability engineering and cost analysis. The system also maintains a full audit trail of every inventory action, from condition changes and usage metrics to repair costs and location updates. Generate audit-ready, condition-based PDF reports that provide a clear snapshot of each item’s current state, historical usage, and visuals—ideal for maintenance planning, procurement, and compliance.

Frame Rebuilding -Track, Measure, and Standardize the Rebuild Process

Gain full visibility and control over the chain and frame rebuild process. This Software tool enables disassembly, cleaning, inspection, and rebuilds to be completed to OEM specifications — all with complete documentation, measurements, images and traceability.

Rebuilds with Precision & Traceability

Standardised Process: Step-by-step SOP ensures rebuilds meet OEM specifications every time.

Visual Documentation: Each stage is tracked with detailed measurements, images, and notes — from crack detection to final assembly.

Data-Driven Rebuilds: Build a complete history of each component’s rebuild, creating accurate forecasts for future rebuild hours and costs.

Compliance & Quality Assurance: Confidently audit, quote, and deliver consistent rebuilds with full traceability.

Forecasting -Turn Usage and Inspection Data into Repair & Replacement Forecasts

Unlock the full potential of your undercarriage data with a powerful, integrated platform designed to drive smarter, faster, and more cost-effective decisions.

Predictive Forecasting:

Each inspection delivers a projected residual life in both hours and distance, helping you anticipate component replacement needs.

Machine-to-Fleet View:

Forecasts are built at the individual machine level and rolled up to provide a comprehensive 12-month fleet-wide forecast.

Real-Time Updates:

Forecasts are continuously refined with each new inspection and machine usage update.

Optimised Procurement:

Plan and order replacement components early to take advantage of bulk pricing and supplier lead times.

Reduced Downtime Costs:

Eliminate the need for costly emergency purchases and urgent deliveries through proactive planning.

Fleet Reporting -Fleet Intelligence at your fingertips Visualized with Power BI

TrackTreads integrates with Power BI to deliver powerful visual reports that provide deep insights into your fleet’s undercarriage performance — past, present, and future. These dashboards enable management teams to make informed, data-backed decisions at both site and fleet levels.

Fleet Snapshot:

Monitor current component condition, residual life, inspection accuracy, inspector performance KPIs, and outstanding maintenance tasks — all in one view.

Historical Benchmarking:

Compare actual component life (in hours or distance) against benchmarks. Identify value lost due to early replacements and underutilisation.

Cost Performance Analysis:

Track component life in terms of cost per hour or per mile/km, enabling precise performance evaluation and cost control.

Future Forecasting:

Access 12-month forward-looking projections of undercarriage repairs and replacements built machine by machine to Fleet level.

Help And Support - Comprehensive Help and Training For effective undercarriage Management

Our training program is designed to empower every stakeholder in the undercarriage management process:

Inspectors gain hands-on skills to accurately measure components using a variety of tools.

Data Interpreters develop the expertise to analyse wear data and identify key trends.

Management is equipped to action results via informed decisions that maximise undercarriage performance at an achievable low cost per hour.

This is delivered through a structured framework that includes:

Detailed instructional videos and step-by-step guides for measuring each undercarriage component with the different types of tools

Visual indicators to recognise signs of accelerated wear

Hardcopy manuals for on-site reference

Together, these resources ensure consistency, accuracy, and knowledge throughout the undercarriage inspection and management process.

Benefits - The Opportunity: Transform Data into Smarter Decision

Unlock the full potential of your undercarriage data with a powerful, integrated platform designed to drive smarter, faster, and more cost-effective decisions.

Single Unified Platform

Manage your entire tracked fleet through one central system with standardised inspection inputs and consistent, easy-to-interpret reporting.

Complete Undercarriage Lifecycle Management

Track chains, frames, and components from cradle to grave using unique identifiers—capturing every detail across their entire service life.

Data-Driven Performance Insights

Leverage historical data such as Hours, Distance, and % Worn at End of Life to benchmark performance and guide strategic planning.

Residual Life Forecasting

Accurately predict remaining component life—both in hours and distance—for proactive, precision maintenance scheduling.

Reliability-Centred Maintenance

Provide your reliability engineers with the data they need to reduce accelerated wear, extend system life, and improve overall asset reliability.

Future Wear Forecasting

Forecast component wear at the next and subsequent PMs to enable precise 6–12 month planning for maintenance, budgeting, and procurement.

Cross-Brand Performance Benchmarking

Compare component wear and performance across multiple makes and models to optimise fleet reliability and reduce operating costs.

Seamless System Integration

Use standard APIs to move data in and out of the system effortlessly — ensuring full compatibility with your existing maintenance and ERP platforms.

Mixed Fleet Support

Enjoy a truly flexible solution designed to work seamlessly across all makes and models in your fleet—no matter the manufacturer.