Component Rebuild Centre

Breathing New Life into Used Components

Many used components can be rebuilt several times over their life.

Specialised Rebuild Services

Component Rebuild Specialists provide the rebuild services in their specific area of expertise, which means that for some large Fleet operators, their rebuild components can be shipped to multiple Service Providers. In these cases, the Service Provider and the Client need a common platform to track progress, authorisation of extra services and compliance to specification of the work.

Built-In Quality Assurance

Each rebuild is then documented as part of a full audit trail, creating transparency and accountability, while also serving as a quality assurance guarantee against future failures. This ensures that every component rebuild can be measured, verified, and trusted, no matter which Service Provider is involved.

Our Services

The following main Functions covered in this system are:

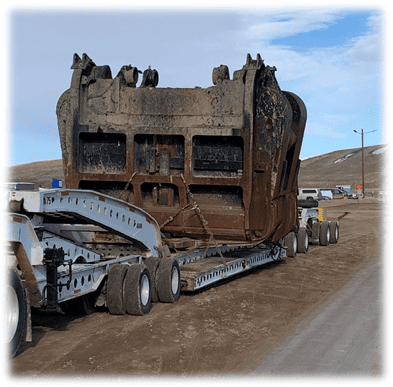

Step 1. Shipping Pre & Post Inspection

Record of Components Shipped with images Components received at the Repairer with images Creates a shipping list with images for instant verification All available on your mobile device

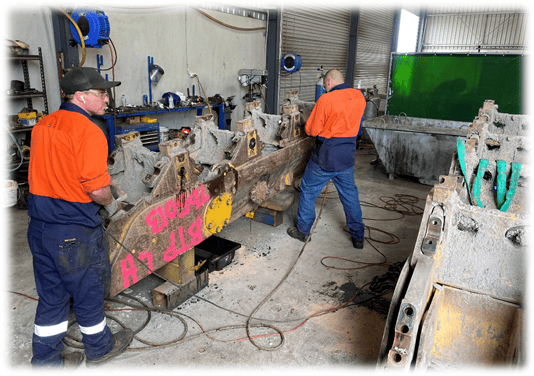

Step 2. Diss-assembly

All components are removed and cleaned Ready for detailed assessment

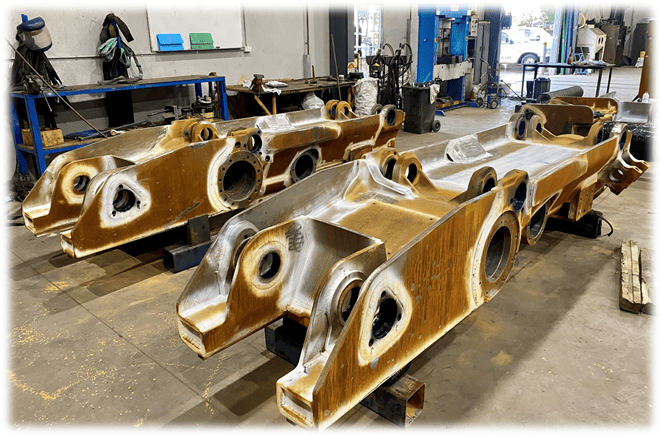

Step 3. Detailed Assessment of Component Condition

In this process, each part of the component is examined minutely, measurements taken of bores, alignments, cracks identified Each Bore is measured and compared to OEM Specification and tolerance. Bore alignments are checked against specification and tolerance Cracks are identified, gouged, and measured Wear material thickness is measured, and integrity checked Welds are assessed

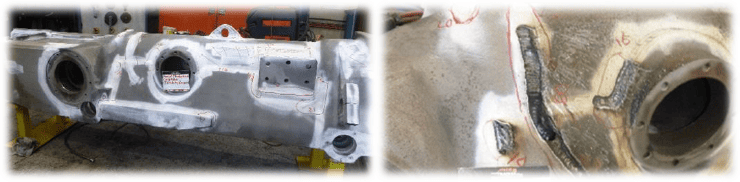

Step 4. Development of a SOW including

This includes a complete detailed listing of all the work required, replacement parts required and associated costs: – Quantity of hours for each sub-component requiring attention Replacement Wear Material required Replacement parts list Crack lengths requiring welding Bores requiring weld rebuild and machining to new OEM specification Bores requiring machining re-alignment to new OEM specification Updates to chassis components to bring into line with current OEM standard Costs associated with each step of work Authorisations can be set so that work will not commence until the client provides the authorisation. Email alerts can highlight authorisations

Step 5. Work in Progress Inspection and Reporting

Inspections can be completed against each sub-component indicating % completion. All of the individual component % completion flows to the dashboard as an overall project % completion. Multiple images and comments can be included against each component Inspections captured using mobile phone or tablet in the workshop

Dashboard

Summary

The entire project is summarised to the dashboard for overall review

Alerts:

Alerts are raised where attention or authorisations are required

Emails:

Email alerts can be included for further notifications