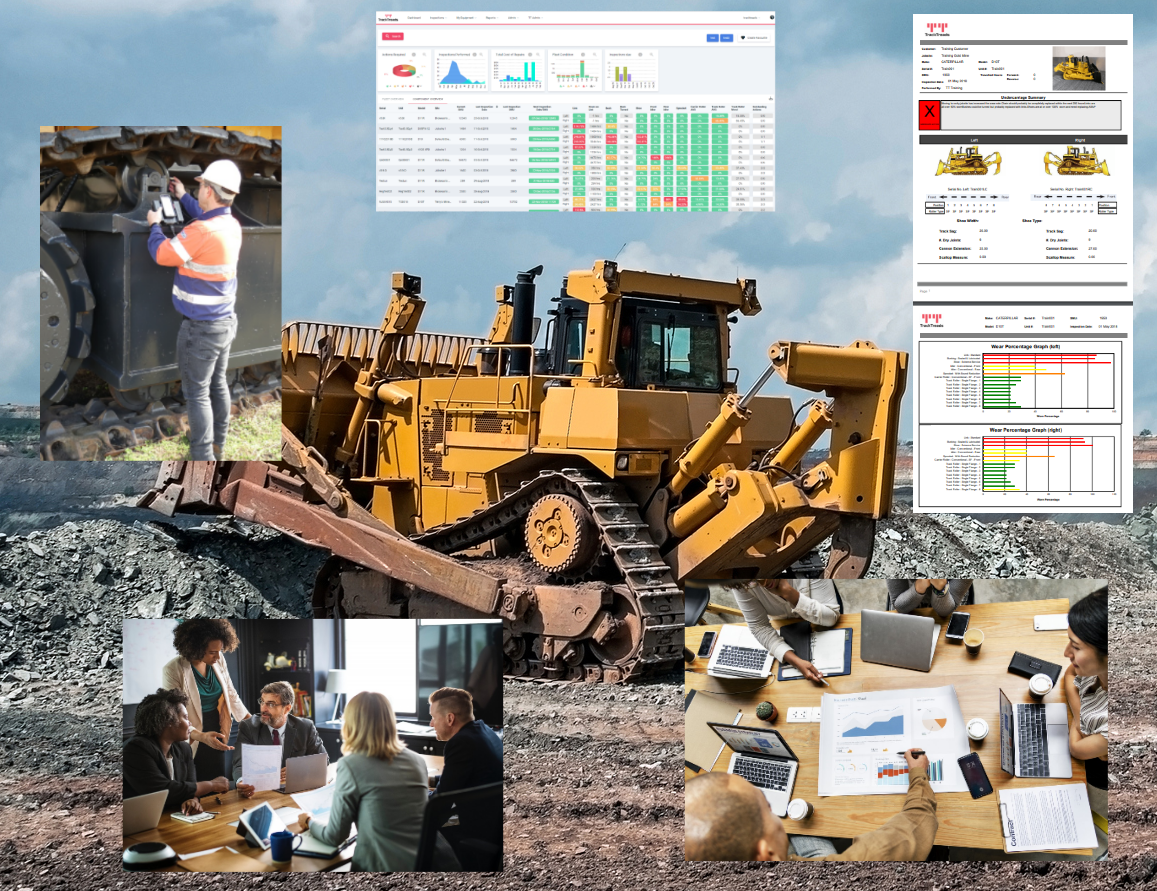

TrackTreads

I Love my Job – TrackTreads Onsite Undercarriage Inspection Training.

This month during our TrackTreads onsite Undercarriage training, I visited some wonderful new people as well existing colleagues in the United States and Canada I would like to thank everyone who participated in the training from Texas, Kansas City, Mississippi, Arkansas, Tennessee, Wisconsin, Indiana to Alberta. I would also like to thank everyone for their hospitality and goodwill and look forward to working with you all soon again. I would like to make special mention Read more…