Reliability Engineering

Use Undercarriage Inspections to fight the impact of inflation

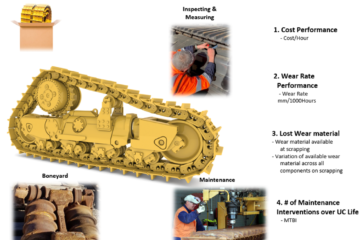

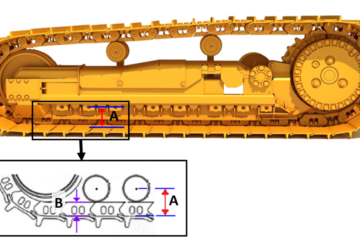

Track Inspections serve a number of purposes, but a few of the more important reasons are: In the image below, the budget life, of the undercarriage components for a large Dozer, is 8,000 hours, and the cost of replacing the undercarriage is $250,000. Thus, in the above example the undercarriage would be replaced 3 times – 8,000 hours, 16,000 hours and 24,000 machine hours, and the total cost would be $750,000 or $31.25/hour In a Read more…