TrackTreads: Your Roadmap to Maintenance and Forecasting

TrackTreads helps customers transform raw Undercarriage Inspection data from the field into actionable insights, creating a clear roadmap for planned maintenance, replacement forecasting, and accurate budgeting. By leveraging historical performance, TrackTreads establishes benchmarks that enable powerful comparisons and smarter decisions for the future.

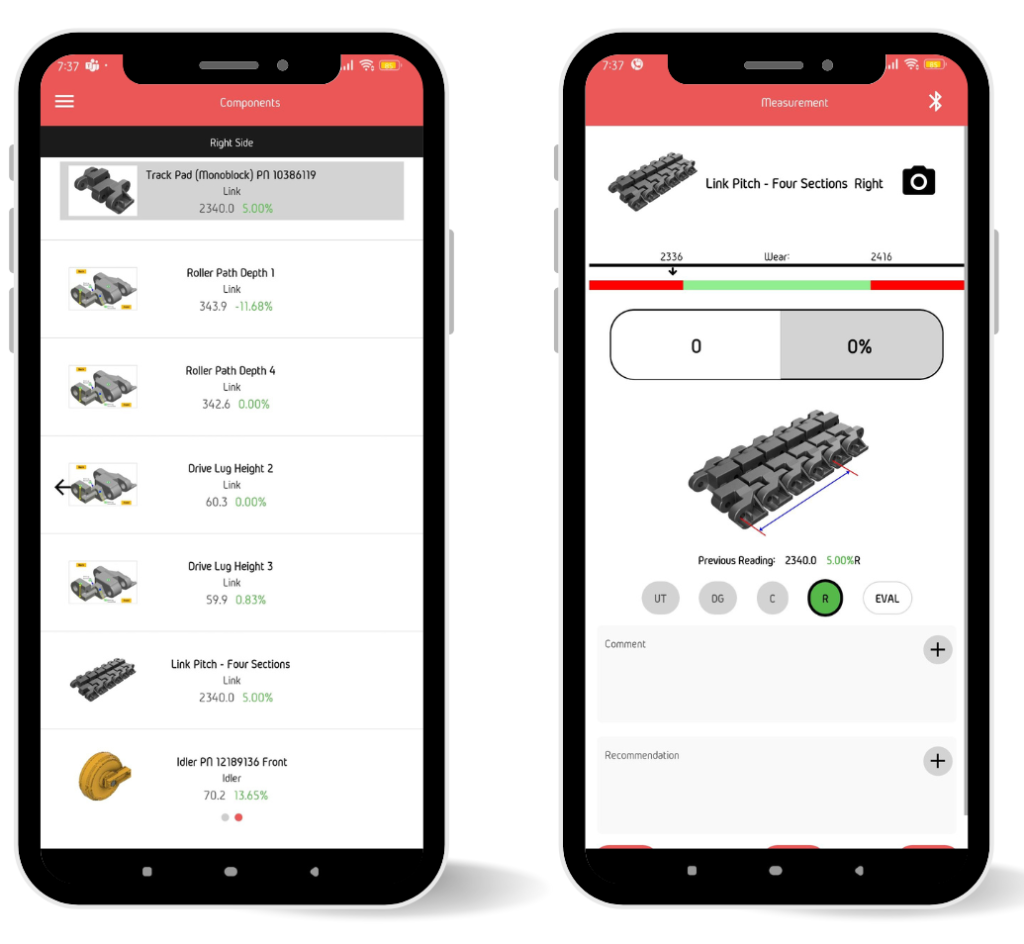

Field Data Collection

Accurate, real-time inspection data is captured directly in the field using our mobile app — available on both Android and Apple devices. This ensures every measurement, image, and observation is consistent and reliable, forming the foundation of informed decision-making

Bluetooth – Connects with ultra-sonic tool

Camera – attaches images to components

Limits – 0% and 100% dimensions for quick

Worn– Calculates automatically

Measurement image – quick reference for how to measure this component with the tool

Previous Inspection Reading– For comparison

Multiple Tool – Manual and ultra-sonic

Comments – For later reference

Corrective Actions – Future W/O to be actioned

Interpretation & Analysis

Unlock the full value of your inspection data with our powerful web-based analysis and reporting platform. Designed for efficiency, collaboration, and insight, this facility empowers your team to determine current component health and identify the right maintenance actions — with precise timing to ensure equipment uptime is maximised.

Reporting & Insights

We deliver actionable insights at both operational and strategic levels through two powerful reporting formats:

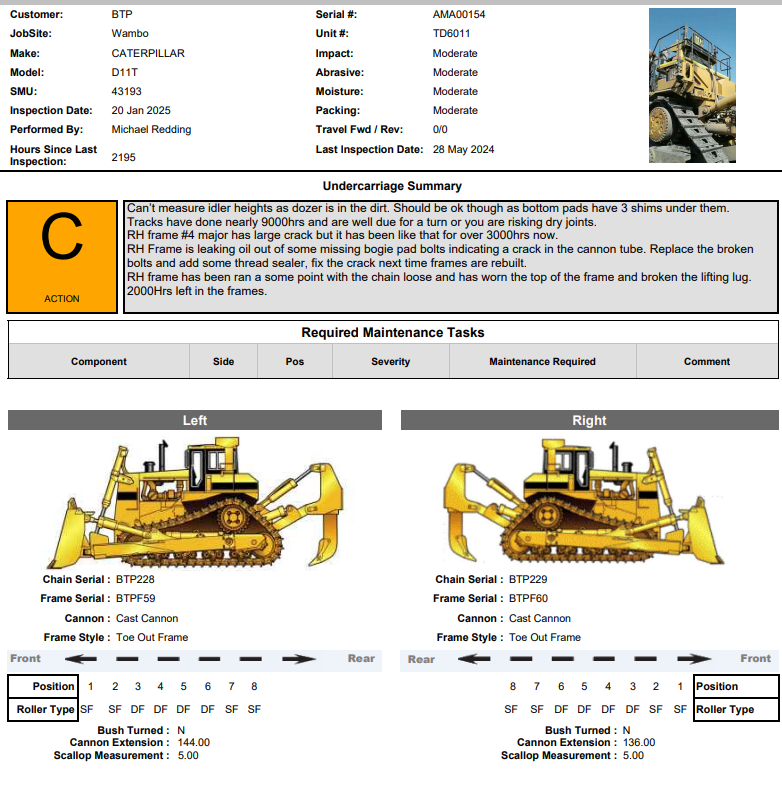

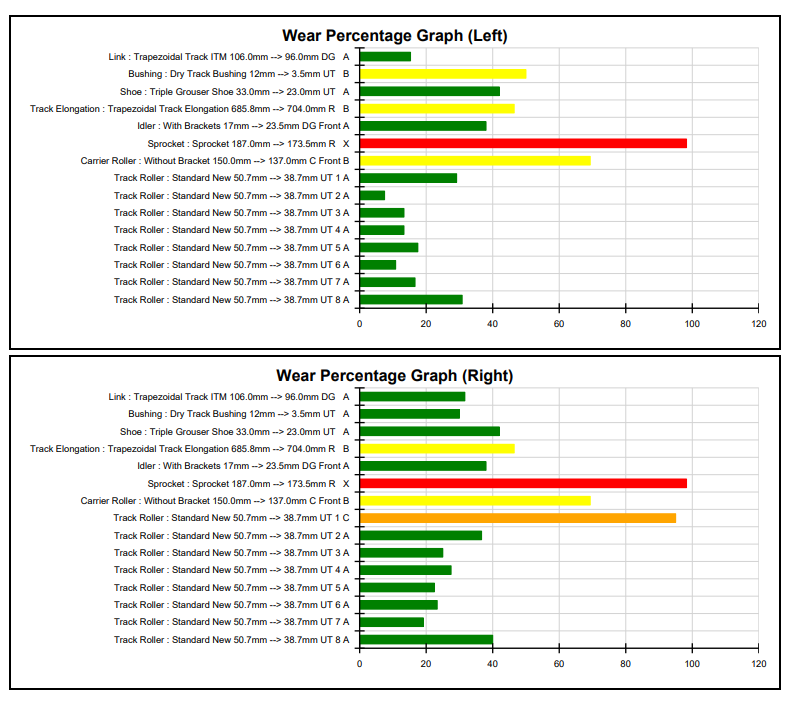

Inspection Report – A detailed, machine-level report that includes:

Component % worn

Total hours and distance travelled

Estimated remaining service life

High-resolution images for visual context Each report builds a complete narrative, supporting maintenance planning and compliance.

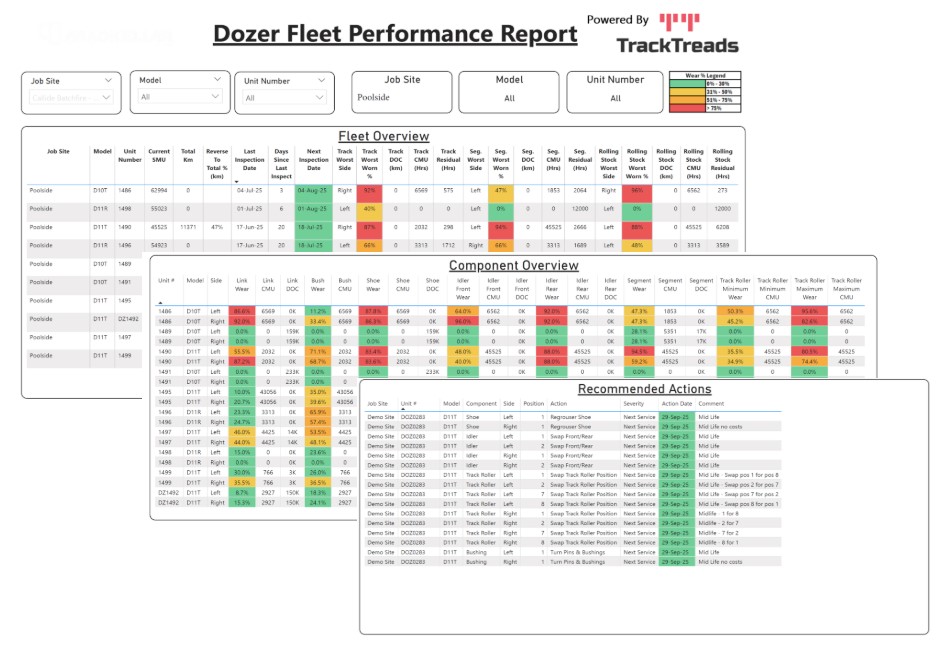

Fleet Power BI Dashboard

A live, interactive dashboard offering comprehensive visibility across the fleet with insights grouped into four key focus areas

Current Fleet Condition – Real-time health status of all undercarriage components

Outstanding Maintenance Tasks – Machine-specific maintenance priorities, ranked by urgency

Historical Performance – Tracks component life at removal (% worn, hours, distance), benchmarked for performance analysis

Future Undercarriage Maintenance Plan – A 6–12 month predictive maintenance roadmap, outlining component replacements, hour meter targets, scheduled dates, and estimated costs — perfect for budgeting, procurement, and inventory planning

Maintenance Execution & Inventory Control

Once maintenance is scheduled, all tasks are executed and recorded within the system. Replacement parts and components are ordered, tracked, and managed, ensuring full inventory visibility and alignment with upcoming service needs

About TrackTreads

At TrackTreads, our mission is to make undercarriage management accessible, accurate, and actionable—no matter the machine or the user. From compact 2-ton tracked excavators to massive electric rope shovels, our solutions are built to support all tracked equipment types including dozers, drills, and face shovels.

We empower inspectors with the same level of insight typically reserved for OEMs and their dealers by delivering the knowledge, tools, and data needed to:

Access wear specifications tailored to specific tools and models

Measure components correctly to ensure accurate evaluations against wear limits

Identify accelerated wear patterns and diagnose root causes that shorten component life

Our Team and Support

Headquartered in Melbourne, Australia, our team includes specialists in web and mobile development, Telerik technology, and Power BI report design.

We also offer hands-on support and training, helping users get the most from the software—from taking correct measurements to fixing mistakes in data entry (because everyone makes them!).

With Infotrak, undercarriage intelligence is no longer out of reach—it’s in your hands.

Latest Articles

Trays and Buckets

This module enables inspection and lifecycle management of trays and buckets, including wear areas, GET performance, and cracking. Performance is analysed in tons/hour, cost/hour, and cost/ton, providing complete visibility from cradle to grave. Key Capabilities Immediate Benefits

Tread Carefully: Measuring Hydraulic Shovel Undercarriage Life Accurately

Tread Path Depth and Pitch Elongation are two critical indicators used to assess the current wear level of a Hydraulic Shovel’s undercarriage, and more importantly, to estimate the remaining service

Stay Ahead of the Shortages: Strategies for Undercarriage Component Security

Keeping the Dozers working through Turbulent Times

Revealing Hidden Value in Your Undercarriage Data

Undercarriage inspection data provides a wealth of valuable insights that can drive smarter maintenance decisions, improve fleet reliability, and optimize costs. To maximize its impact, this information should be organized

From Data to Information: The Story Behind Every Undercarriage Image

Images captured during Track Inspections do more than just illustrate—they help tell the full story of undercarriage wear. Every inspection aims to uncover how Track Parts are performing over time,