Tread Path Depth and Pitch Elongation are two critical indicators used to assess the current wear level of a Hydraulic Shovel’s undercarriage, and more importantly, to estimate the remaining service life of its components.

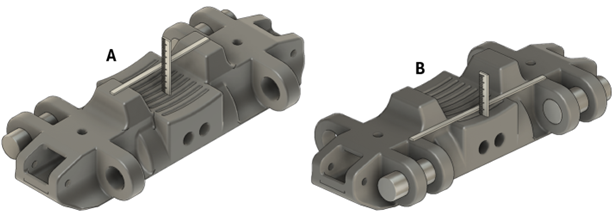

Tread Path Depth can be measured in two ways:

- From the top of the Drive Lug (Figure A)

- From the Base of the Drive Lug to the bottom of the Tread Path (Figure B)

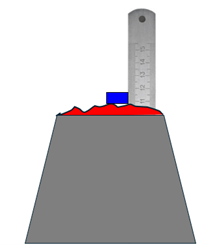

While the top-of-lug method (Figure A) is commonly used, it presents challenges. The drive lug often becomes bruised or deformed during operation—metal is displaced upward, as highlighted in red in the schematic. This distortion can lead to inaccurate depth readings unless the deformation is accounted for or removed from the measurement. In practice, correcting for this can be difficult and unreliable.

A more consistent and accurate method is to measure from the base of the Drive Lug to the bottom of the Tread Path, as shown in Figure B. This approach avoids the variability introduced by surface damage on the lug top.

Additionally, it’s important to note that as the Tread Path wears down, the material tends to work harden. This hardening effect results in a reduction in wear rate over time, adding complexity—but also potential longevity—to undercarriage life projections.

Need Help Measuring Undercarriage Shovel Components, contact us at www.tracktreads.com