Every machine is built from components, each with a different service life. Traditionally, life is tracked against a budgeted target, but this often fails to reflect the true condition of the component.

By combining actual operating hours with condition-based inspections, Asset Managers gain a more accurate picture of component life:

- Budget Life – Planned life in a given environment.

- Component Hours – Actual hours already worked.

- Residual Hours – Remaining life calculated from condition (via oil sampling, wear tools, or ultrasonics).

- Total Projected Life – A true forecast that combines actual hours with measured residual life.

This approach transforms raw inspection data into actionable insights, helping Asset Managers:

- Plan maintenance with greater confidence

- Accurately forecast replacements and budgets

- Extend asset life and reduce operating costs

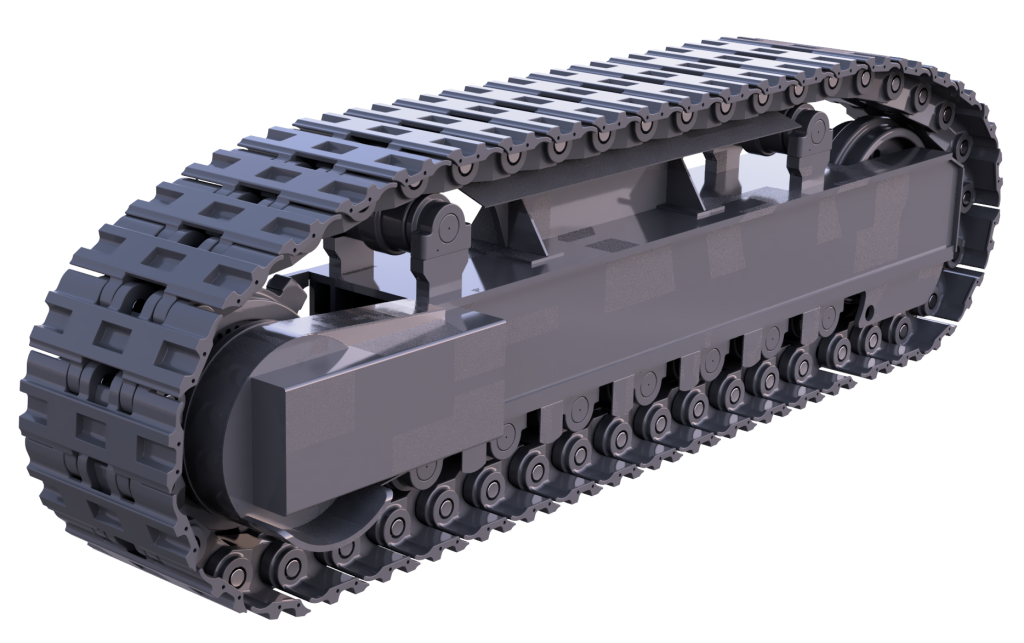

TrackTreads converts Condition to Clarity with Inspection Tools that Strengthen Asset Management Systems