Tires are high-pressure vessels on which the wear is measured typically by measuring the depth of available tread with at least 3 points being taken across the face of the tire to provide a reasonable average. The overall condition of the tire will be inspected to identify any visible faults that could lead to failure. Thus, inspection of tires is relative quick and can be carried out by a technician without huge investment in training and experience. Potential faults can be relatively easily identified since they are like a car tire which we all understand. They are just very much larger!!

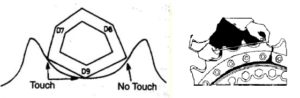

Undercarriage is made up of multiple inter-dependent components each wearing at different rates, each component being measured in a different way using a selection of tools. The selection of tool can vary based on the size of the components; example shown Sprocket

Small and Large Sprocket Measurement

A simple error in measurement in Undercarriage can lead to a large variation in calculated wear resulting in faulty decisions. Multiple signs in the metals wear profile will point to potential accelerated wear which is not immediately discernible to an untrained eye. All the different Undercarriage components need to be managed as a system in order to get the overall system to as close to 100% worn as possible. Technicians performing inspections need to have a greater understanding and skill to complete a rigorous inspection and interpretation of the results. This costs time and money.

Tires and Undercarriage are large $ value items in the maintenance budgets for large earth-moving machines. Undercarriage, by virtue of being more complicated means the potential value or dollars at risk is higher than for the tires per inspection. This is a good indicator as to where the inspection attention needs to be focused