Reliability Engineering

Use Undercarriage Inspections to fight the impact of inflation

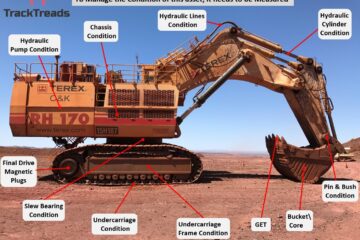

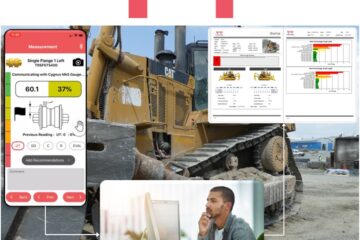

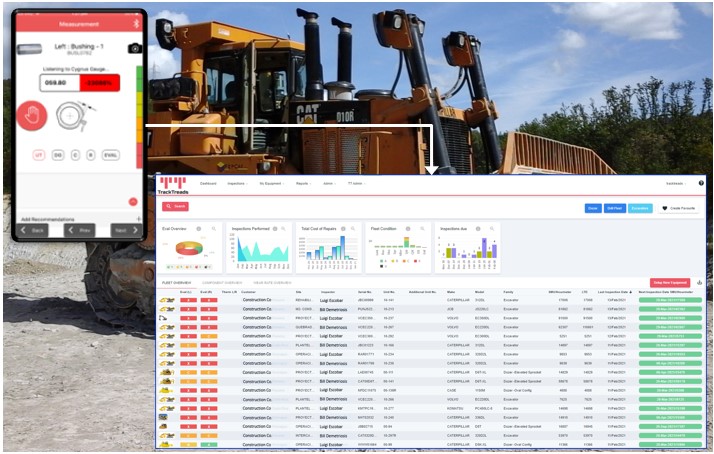

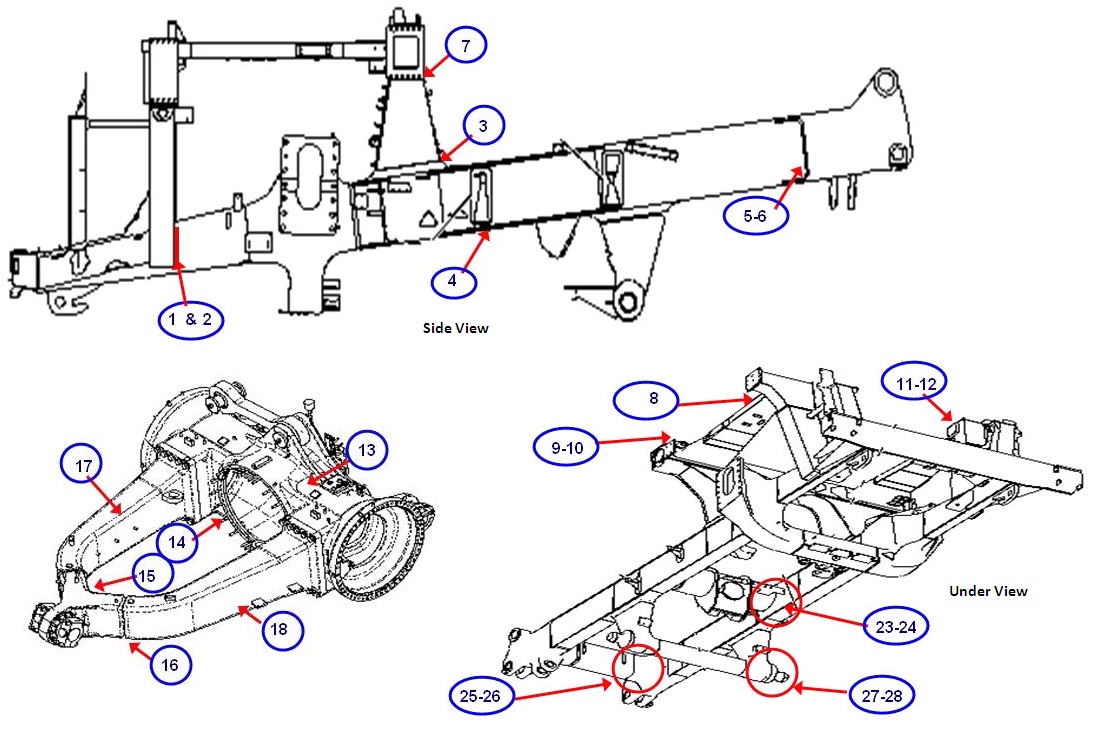

Track Inspections serve a number of purposes, but a few of the more important reasons are: In the image below, the budget life, of the undercarriage components for a large Dozer, is 8,000 hours, and the cost of replacing the undercarriage is $250,000. Thus, in the above example the undercarriage Read more…