Track Inspections serve a number of purposes, but a few of the more important reasons are:

- Identify track components showing signs of accelerated wear and rectify the causes of this.

- Monitoring the wear rate performance of the components

- Identifying the forecast replacement date of the track components

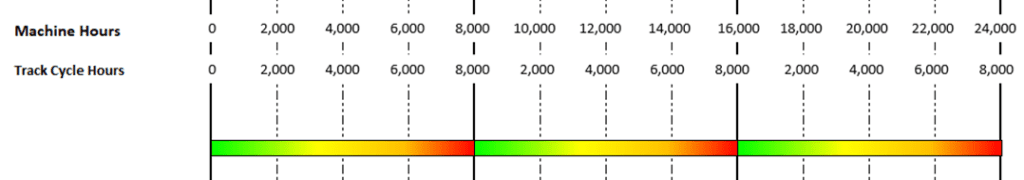

In the image below, the budget life, of the undercarriage components for a large Dozer, is 8,000 hours, and the cost of replacing the undercarriage is $250,000.

Thus, in the above example the undercarriage would be replaced 3 times – 8,000 hours, 16,000 hours and 24,000 machine hours, and the total cost would be $750,000 or $31.25/hour

In a world of higher inflation, managing costs is a must in order to remain profitable. This means avoiding unnecessary expenditure. If undercarriage components do not achieve full life, this is value foregone, or unnecessary expense.

There can be a number of reasons that track components do not achieve full life

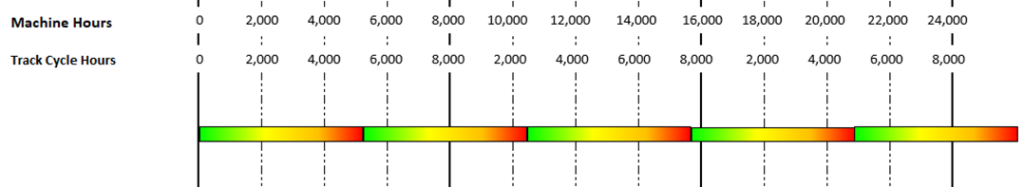

- Track Inspections are not performed, the average life achieved will then not exceed 65% of full life

Accelerated wear on components is not identified early and the track components wear out prematurely.

In this example the undercarriage would be replaced 4.5 times as it does not achieve more than approximately 65% of life. (5,200 hours, 10,400 hrs, 15,600 hrs, 20,800hrs and 25,000 machine hours), and the total cost would be $1,125,000 or $46.87/hour. A significant increase in cost per hour.

Therefore, it stands to reason that as inflation increases the cost of replacement components, it becomes imperative to inspect and manage the undercarriage components more closely.

TrackTreads provides a complete Undercarriage and Inspection Management Solution for all makes and models of tracked machines

0 Comments