Large Mobile Mining Fleet

Mechanical and Structural Inspections

TrackTreads includes within its suite of Field Inspection Software Tools, a module to convert paper forms to digital Inspections. Digital Inspections can cover any type of inspection, from PM Service, Daily- Prestart’s to Mechanical and Structural Reliability Inspections

The software is specifically built to Field Inspect many different aspects of the equipment

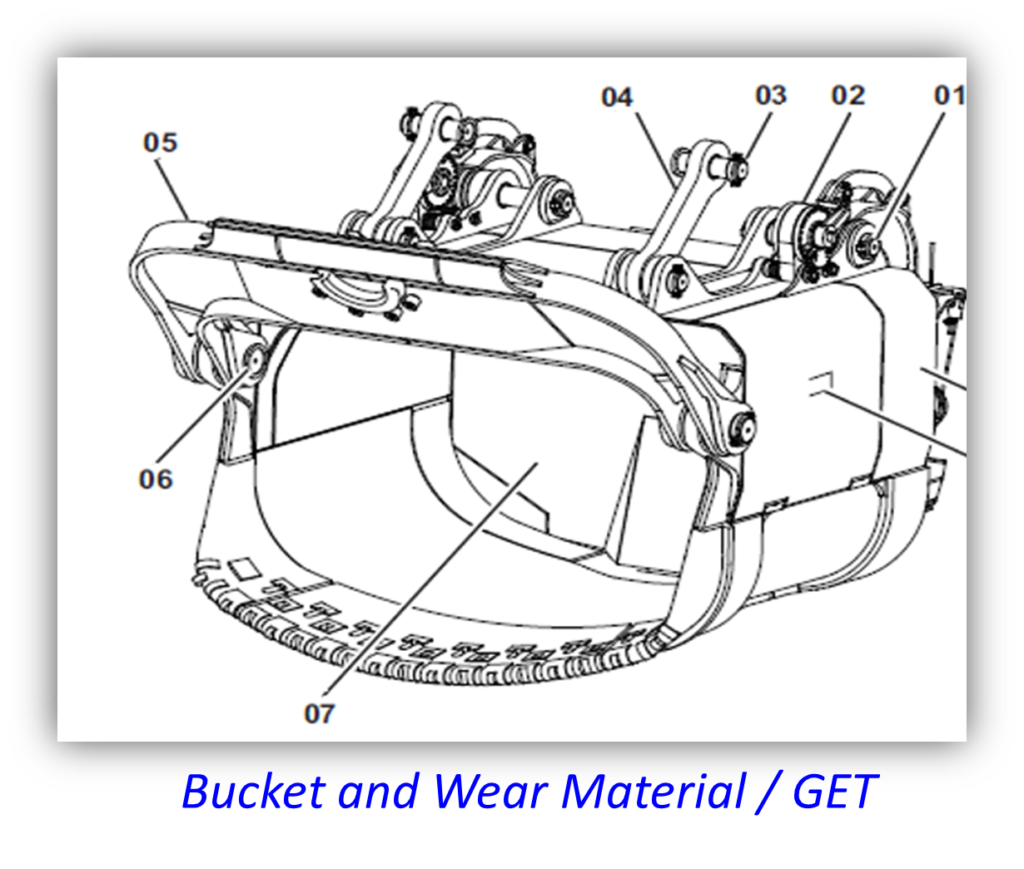

GET

- Tracking Replacements

- Measure wear

- Record Condition

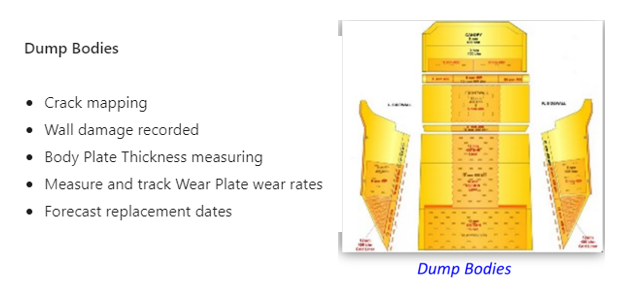

Wear Plates and Component Core

- Measure thickness against predefined limits

- Indicate Condition

Pins and Bushes

- Indicate Condition & measure against specification

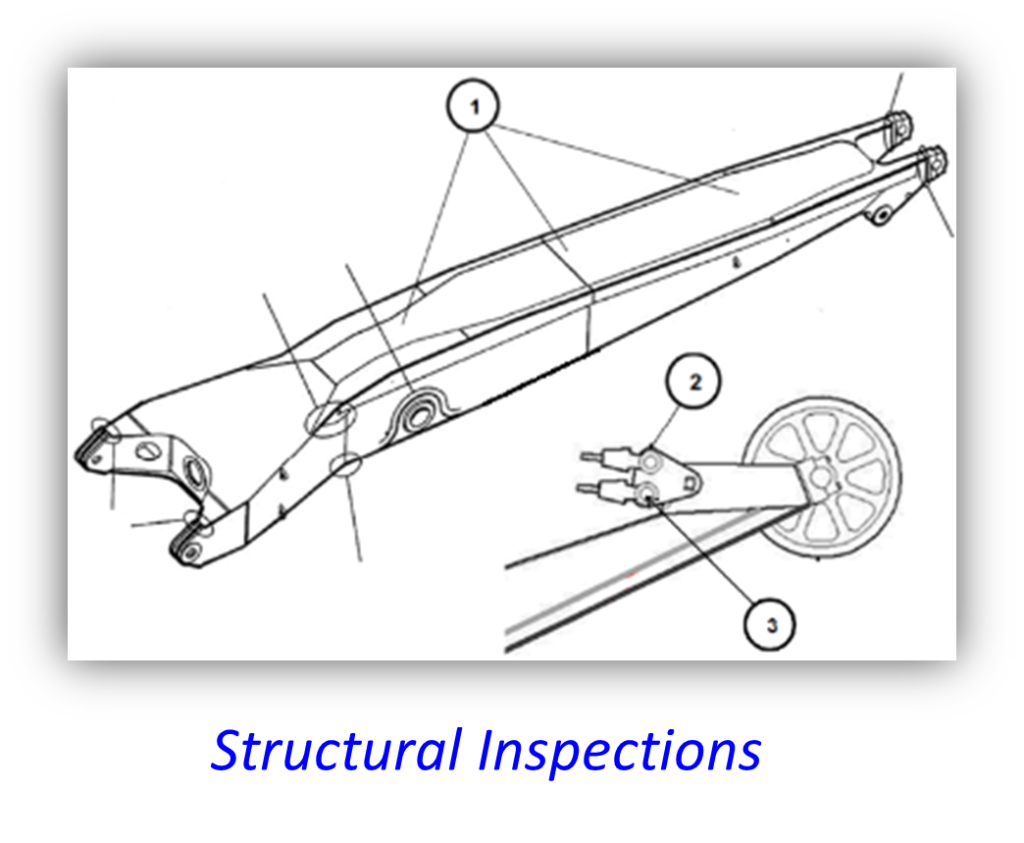

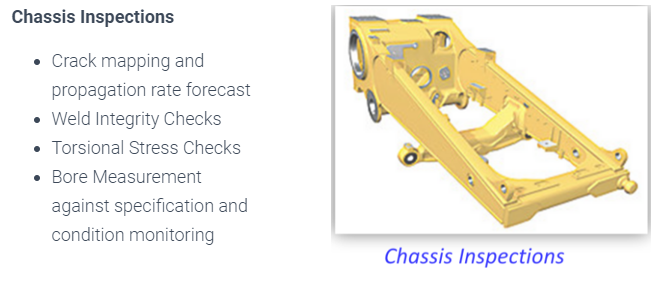

Structural Crack Mapping

- Identify Cracks & perform weld integrity checks

- Draw Cracks on schematics

- Set limits of crack length and forecast repairs

- Toggle to show/hide repaired cracks

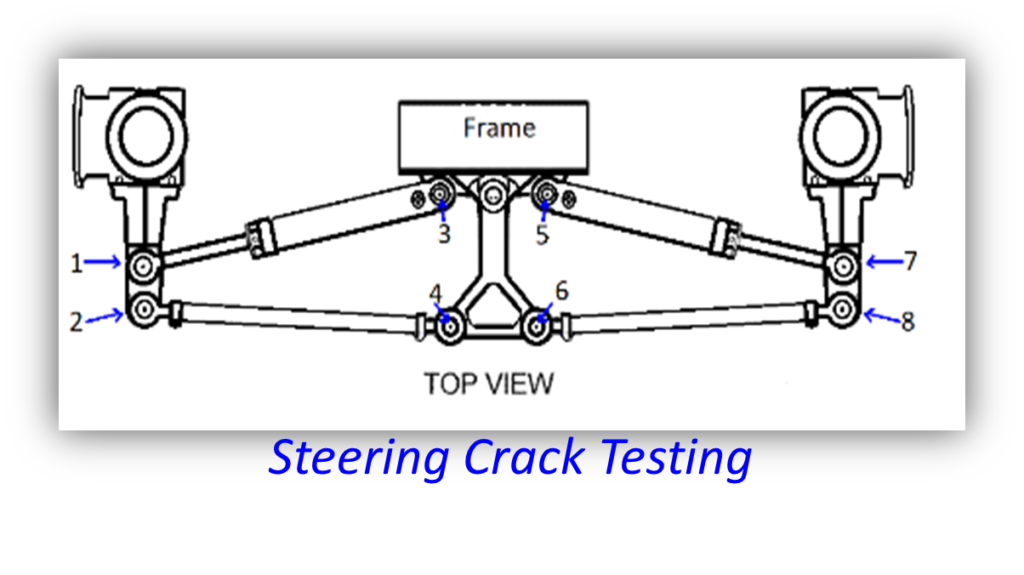

Steering Ball Stud Crack Testing

- Audit Trail of Safety crack testing

- Forecast next inspection & send reminder alerts

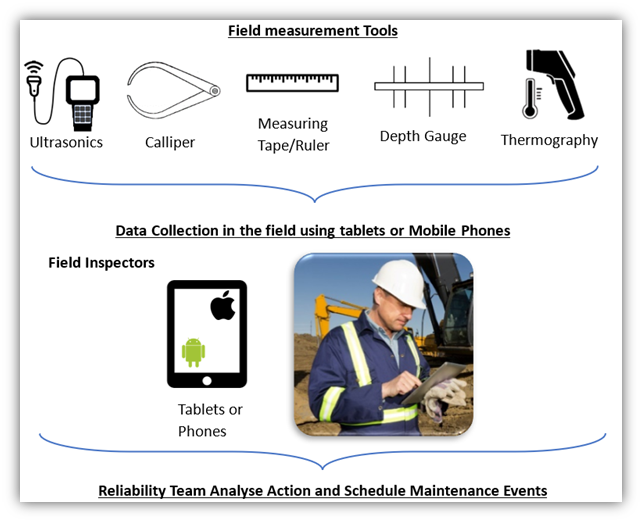

The following process follows the steps

Key Attributes and Benefits of Digitising Inspections

- Makes the task of data collection easier for the inspector by providing not only the diagrams but instructions and previous inspection readings for reference.

- Data is in real time; warning alerts enable supervisors to react quicker

- The digital version of a paper form eliminates many of the shortcomings of paper forms; damaged or lost filed forms, manual data entry, manual labour

- Digital forms empower quicker and more appropriate data driven decisions

- Increases operational efficiency by reducing transcription of data, intensifies quality and accuracy of the data and reports and reduces human error.

- Ensures consistency of data collection across a family of assets

- Diversified work teams can access the data in their own work time and regions

- New Team members can be brought up to speed on the methodology quicker

- Cloud Based Data available in many formats across multiple devices giving portability and availability in predefined reports or as raw data.

- Entire Fleet Condition can be viewed on single dashboard

- Track Crack patterns on a time axis across a Machine Model Chassis or structure

- Residual life forecast for each component is generated from the inspection data

- Corrective Actions can be planned by reliability specialists based on Condition.

- Plan and monitor inspection activity, identify further training where required

- Move data seamlessly to and from the system using standard API’s

- Eliminate unscheduled down time

- Increased visibility to the business by using the cloud platform from workshop to CFO.

- Analyse past 12 months maintenance coststoformulate future 12 months budgets.

- Schedule replacement components reducing the need to carry excessive inventory.

- Improved Audit documentation

- Warranty claims.