Reliability Engineering

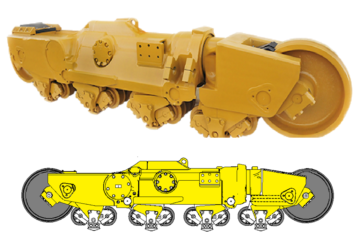

Study of Benchmarks for Undercarriage Management

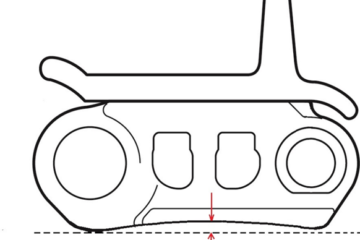

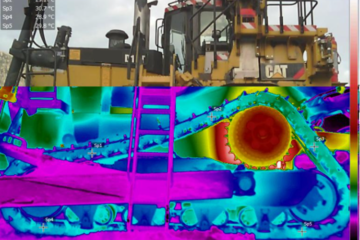

Last year, we were asked by and Asset Manager seeking insights into the average worn percentage of undercarriage components at their end of life. His aim was to establish key performance indicators (KPIs) to measure his team. This inquiry instigated numerous deliberations regarding the definition of average up to exemplary Read more…