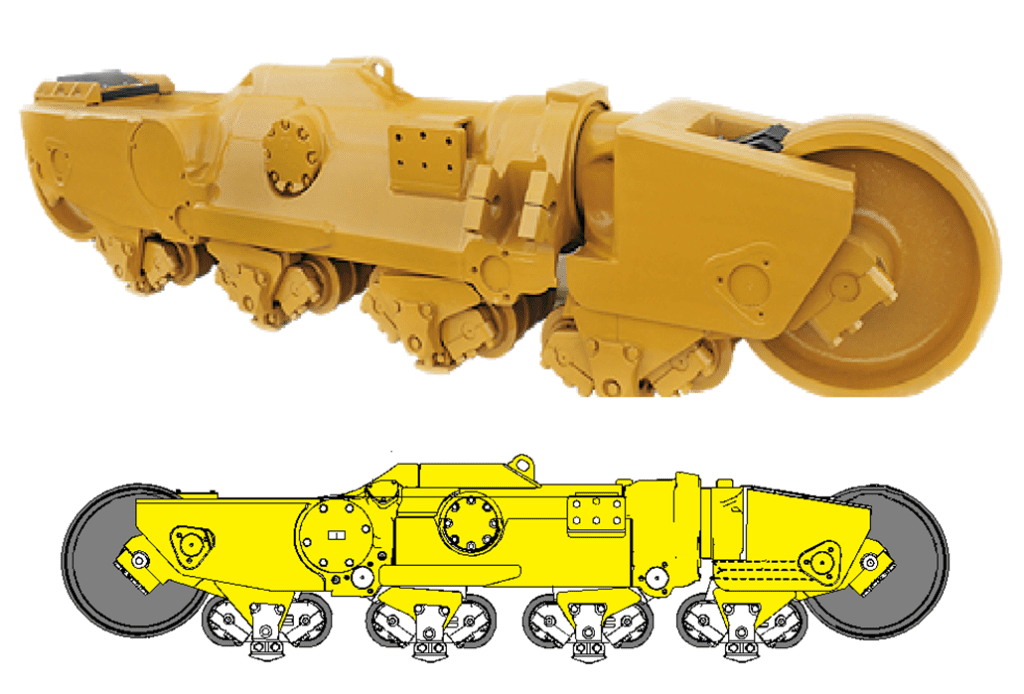

Undercarriage Inspections should also include inspecting the condition of the track frame itself. Track Frames become worn over time and have a finite life. Wear points should be observed and where possible measured to provide an indication of the residual hours available in the frame. Residual hours will provide a forecast future date for the rebuilding or refurbishment of the frame back to as new condition.

Frames that become worn result in accelerated wear of some undercarriage components, which means loss of money or value.

Some areas that should be considered on the frames:-

- Check the condition of the bogie pins

- Look for cracks in the frame, often indicated by oil leaks

- Check for alignment of Idlers and bogies

- Check condition and movement of Equalizer bar attachment points

- Look for oil leaks around pivot shaft articulation point

- Check Bogie pad condition

- Check measurement of Idler ride height

- Check Machine balance

- Check wear condition, hardware and presence of Chain Guides.

- Check the Idler flange wear

- Check the Roller flange wear

All of these observation points can be standard within the TrackTreads Undercarriage Inspection Software ensuring that when you look at the condition of the undercarriage components, the frames are also included. The benefit is ensuring that Track frames are monitored with the same amount of detail.

0 Comments