Scalloping is where the middle of the Link rail becomes hollowed out. This increases the vibration as the chain moves over the components and can lead to a very uncomfortable ride!

Scalloping can be caused by a number of factors: –

- Chain is too tight causing excessive wear as the link moves around the idler. Chain tension must be checked and track sag measured whenever the machine is inspected.

- Too much reversing during machine operation, which again causes wear as the link passes in reverse over the Front Idlers.

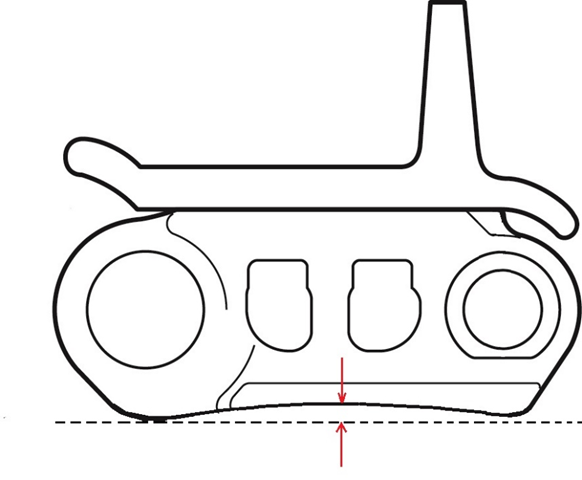

- Worn Bogie pads under the rear bogie causing the Rear Idler to carry the load rather than the bogies and Track Rollers. This can be checked by measuring the Idler Rise Height as well as looking at the condition of the bogie pads. (These pads are often not checked due to safety issues. Shimming these pads can reduce the loading on the Idlers preventing any further degradation of the Link Scalloping. It is important however to measure the Idler Rise Height at each inspection. There is a simple tool to complete this measurement.

Idler Rise Heights are provided within the TrackTreads system for easy measurement at each inspection.

Once the links have become scalloped, they essentially need replacement. This could mean replacement well below the 100% worn mark effectively leading to value being thrown away.

0 Comments