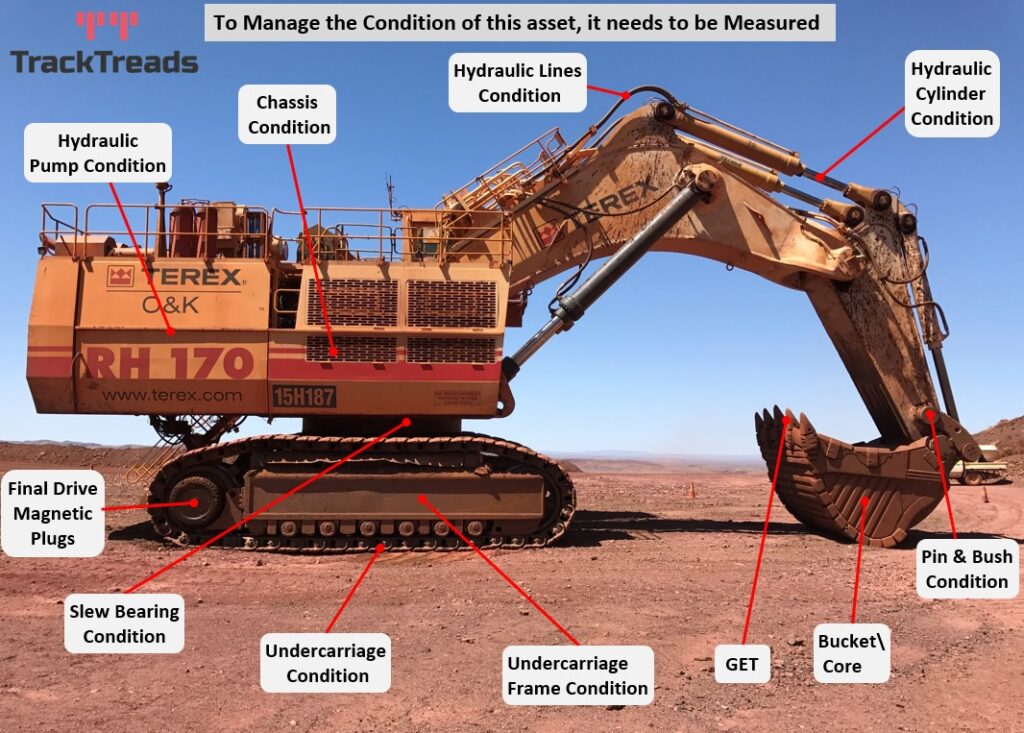

Every component on this machine needs to be regularly inspected to ensure that the machine remains reliable and productive.

It is only as good as its weakest Link!

Taking oil samples and performing PM’s is not enough to ensure Reliability

Every component should be examined on a regular basis to assess its condition and the next potential point of intervention. Examination means a proper assessment not just a quick look.

Engines use oil samples and other condition monitoring tools to determine the internal condition and residual life till the next service or mid-life.

If its not inspected and measured, it cannot be managed

The inspection data collected provides and audit trail of the progression of wear over the component’s life.

The inspection data also provides a yard stick or benchmark against which other machines can be measured. Eventually component lives and interventions can be based on known wear indicators being identified at specific points during the component’s life.

TrackTreads provides a complete solution for collecting Mechanical and structural Field inspection data using a mobile app which syncs with the cloud for further analysis by the Reliability Engineers. Your solution to the entire inspection process.

0 Comments