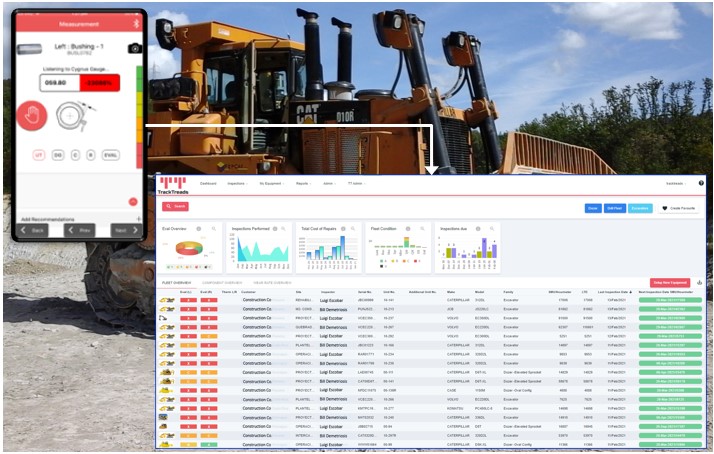

Field Inspections

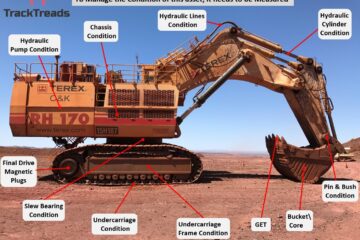

Every Asset is as reliable as its weakest link

Every component on this machine needs to be regularly inspected to ensure that the machine remains reliable and productive. It is only as good as its weakest Link! Taking oil samples and performing PM’s is not enough to ensure Reliability Every component should be examined on a regular basis to Read more…