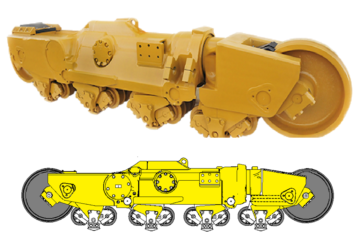

Undercarriage Inspections involve measuring each component using diferent tools and then using formula to calculate the % worn of the undercarriage components and the condition of the Undercarriage System. The percent worn of the component wear surface is then used to calculate the remaining life on each of the components. This can be added to the life already lived on each component providing a calculated value for the full life that component can then achieve. This is very useful data which can then be used to:

- Improve Cashflow – Knowing when components are to be replaced enables replacement components to be ordered just in time without the need to carry buffer stock in-case.

- Improve Profitability – Knowing the life that the components will achieve, enables the components to be taken to close to 100% worn. The more wear and life that can be obtained from each component and the undercarriage system, the more savings that are achieved and the lower cost per hour of operation. Identifying accelerated wear also enables corrective actions to be taken early thus preserving the achievable life of the components.

- Maintenance Scheduling – knowing when undercarriage components are due for replacement or repair enables maintenance to be planned well in advance, This ensures more uptime for the equipment resulting in greater productivity.

Contact TrackTreads today to help you get started

0 Comments