Undercarriage can make up more than 50% of the maintenance costs of a machine. Therefore, managing this wear surface can deliver large $ savings. Utilizing Undercarriage Software requires integrating the inspections into the daily inspection routine across the job site. Points to consider when calculating the ROI:-

- Time and accuracy to complete an inspection

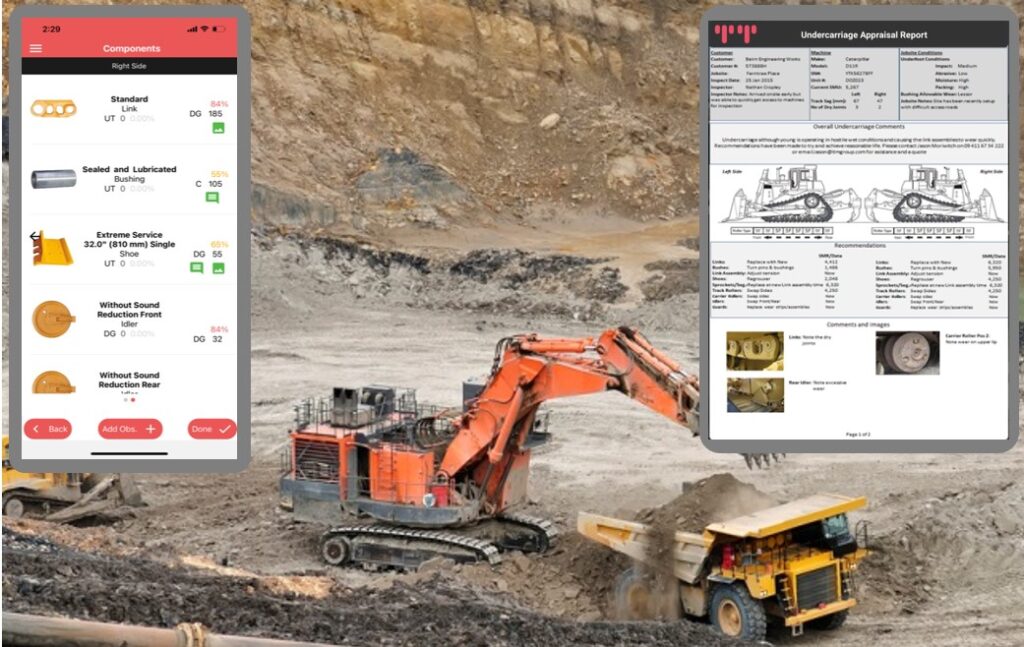

The ultrasonic measurements with the mobile phone app enables immediate percent worn calculations and comparisons with prior inspection measurements to improve accuracy of inspection results.

The real timesaver is in the transfer of data & images previously taking anything between 1 to 5 hours depending on size of machine. This is now instantaneous, and is supported with all the previous wear results to show the trend in real time.

- Identifying problems causing excessive wear rates

Successive inspections enable identification of increased component wear rates and the actions required to bring the wear rates back in line with average, whether it’s tight track, operator skill or any of the myriad causes of increased wear rates.

- Matching components and actions to gain as close to 100% life

Regular undercarriage inspections over the life of equipment allow repairs to be identified to enable all components in the undercarriage system to get as close to 100% worn. Any component not achieving 100% worn effectively means money is being left on the table resulting in a higher cost per hour.

- Forecasting component replacements to reduce emergency delivery costs and unplanned downtime

Every jobsite aims for nil unplanned downtime and to have the required components ready to be available for installation on replacement. Inspection data provides residual life data for the components and a list of recommended action tasks for maintenance planning

- Matching components to the correct environment – monitoring performance

Every jobsite has different conditions and matching the correct components to the environment saves the component from premature excessive wear. Monitoring components wear rate performance over successive inspections allows a benchmark standard to be set for the environment against which all other components can then be monitored thus allowing you to develop your Undercarriage Selection and Purchase Guidelines.

- Validating Warranty claims

Warranty claims can be validated with real inspection data allowing surety for both the manufacturer and the customer. Usage and benefit already obtained by the customer can also be validated ensuring no possible conflict by either party. Without data, no claim can be justified and money is lost by one party causing dissatisfaction.

- Managing mixed Fleets

Reduce the time and effort understanding different manufactures reports. Tracks treads support all brands with inspection reports in a standardised format across the entire fleet. All wear limit calculations are based on the OEM specification ensuring accuracy and peace of mind that the wear rates are correct.

The ROI for each jobsite will be different depending on how well the undercarriage is currently managed.

“Customers found that moving to the TrackTreads Undercarriage Management system removed the time and energy needed to manipulate inspection data, instead empowering them to make key management decisions based on the comprehensive analysis provided by the TrackTreads system.”

0 Comments