Managing Undercarriage Bush Turns to save money requires skill, inspection data and systems to accumulate the data. Under Covid-19 conditions, many companies operating tracked fleets may need to manage this in-house, since supplier inspectors are not currently able to visit the machines. Technology can now provide solutions to this challenge. Looking at Bush wear, the skill is identifying the point where the bushes can be turned and whether it is economically viable to do this. This skill can be learnt.

Consider the following:-

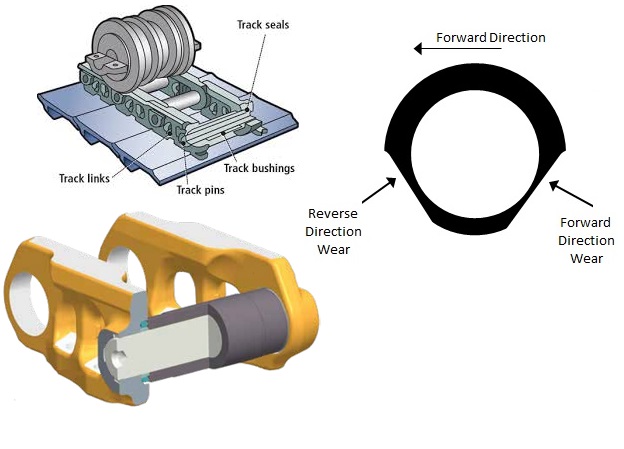

Bushes wear on one half of the bush for lubricated track until the bush is turned.

Turning the bush allows the other half of the bush to wear equally. If the bush is worn past a certain point, it becomes impractical to turn it, which then might limit the life of the undercarriage.

Where the bush is worn out, and the other components have not worn to 100%, there is then a loss of the value of the sacrificial material still available on the other components. The whole objective is to get the entire undercarriage system to wear out equally to 100% worn.

Bush life in undercarriage is dependent on the underfoot conditions, the moisture content of the material in which the machine operates along with the abrasiveness of the material. The harsher any of these factors, the higher the wear rate.

There are 3 factors to consider when determining whether to turn bushes and at what point to turn: –

- Bush wear to 100% worn before first turn – If the wear on the bush is 1 to 1 with link (I.e. wearing at the same rate as the link), a bush turn might not be a consideration. Where this is not the case, and bush life before turn is a limiting factor, it needs to be turned before it is worn out so that the other side of the bush can be utilized.

- Seal Life to 100% worn hours – the seal can often be the limiting factor and if they are worn ( no longer sealing and allowing oil to leak out and dirt to get in) will need to be replaced, this might be the time to complete the bush turn. Some of the seals will achieve the same life as the links, but if not, they become a limiting factor for the life of the chain. Replacement allows longer wear of the chain.

- 50% of Link Wear Compared with Bush Wear – at 50% wear on the link, is the bush close to 80 or 90% worn so that a turn will allow the link to wear out the remaining 50% – what is then cost of performing the turn including the use of swing chain, freight etc against the cost of running it to destruction and then the lost value of components that have not achieved 100% worn.

The technology to collect and manage the inspection data is available through the TrackTreads online Undercarriage Management System along with Android and IOS mobile apps to capture measurements in the field. Inspection kits are available to measure any brand and model of machine. This helps users to predict Undercarriage Bush Turns and save money. See also:https://www.bux-montundercarriage.com/blog/15-the-importance-of-pin-and-bushing-turning

To get further information and arrange a free demonstration simply fill in the form below.

[contact-form-7 id=”2772″]