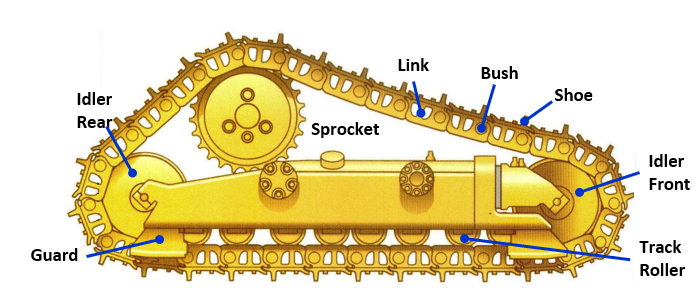

The TrackTreads Undercarriage (UC) Management Software enables UC inspectors to measure Undercarriage components in the field using the Mobile Application connected with an Ultrasonic Tool. This requires each component to be defined. The Undercarriage system is comprised of multiple different components each with their own wear profile definition.

Each OEM UC component is heat treated and hardened in specific ways and to different depths, to resist wear. This will define each components wear profile with a specific wear curve and formula. The wear curve can be defined by a straight line, polynomial, inflection point or stepped. Each component will also have a low and high impact wear curve to account for the jobsite conditions which could limit component life.

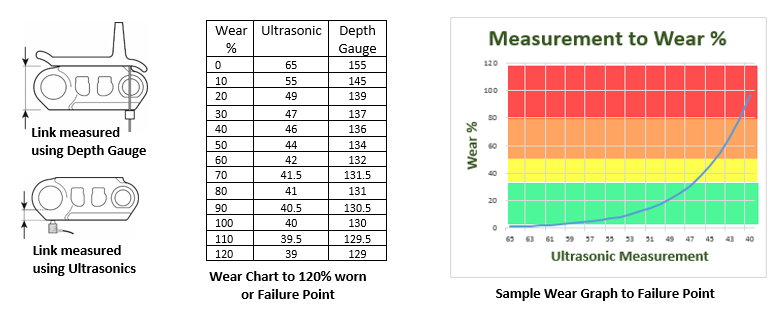

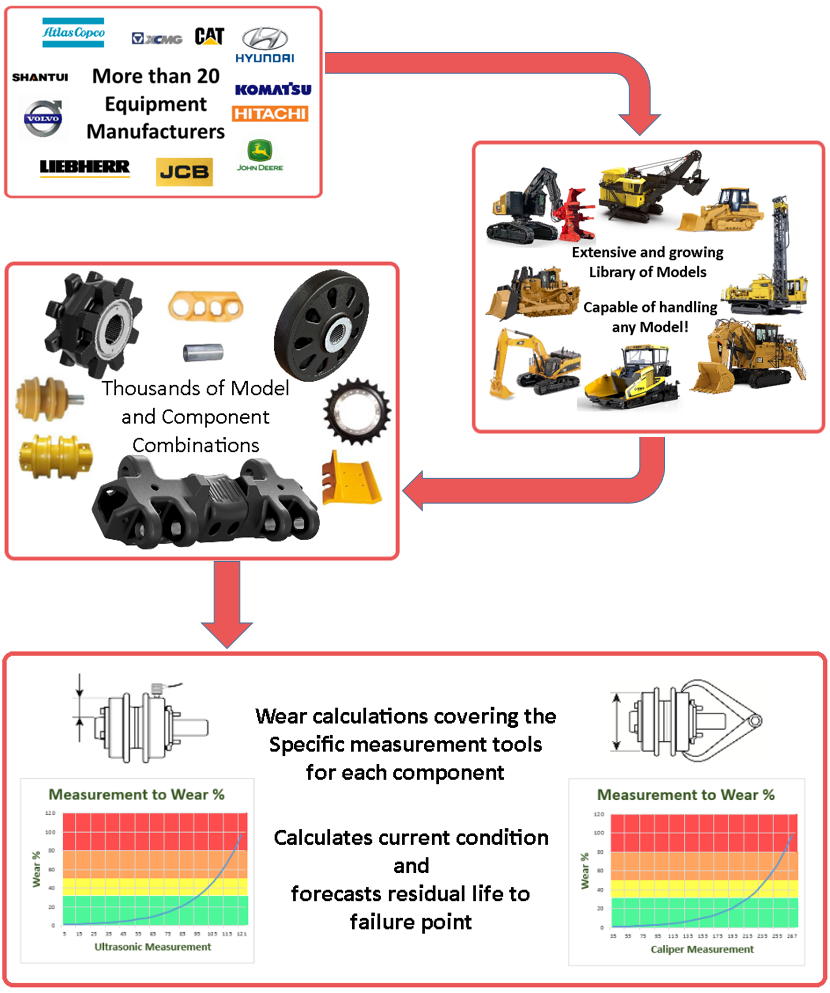

Each component can then be measured with 1 of 4 tools: Ultrasonics’, Calliper, Depth Gauge and Tape Measure, for example:

When a component measurement is entered, TrackTreads automatically calculates the percent worn using the formula defined by the wear profile and failure point for that component and measuring tool used.

The calculated wear percentage is compared to the hours on the wear surface to derive the forecast residual hours.

TrackTreads offers an extensive and ever growing range of manufacturers, models and components. More are being added constantly and we can support any model you ma require.

To get further information and arrange a free demontration simply fill in the form below.

[contact-form-7 id=”2772″]