Every earth moving operator will faithfully ensure Oil Samples are taken to determine the internal health of the engine, transmission etc. It is normally part of the warranty requirement on the machine or those components. Every Oil sample analysis report is examined carefully for any signs of potential failure to ensure that the component (example “Engine”) achieves its desired target life.

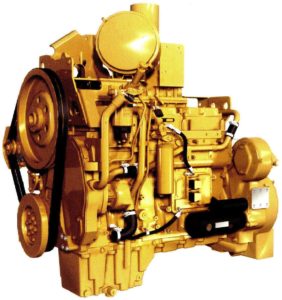

Engine Cost – $250,000 (Cost of a rebuild on average)

Average Life achieved = 18,000 hours

Cost per Hour = $13.89 per hour

Sampled on average every 250 Hours at a cost of between $15 and $25 per sample

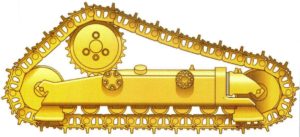

Undercarriage is either inspected by internal inspectors or outside assistance from the Dealer or Service Provider is relied on to inspect, interpret and provide a report on the condition of the Undercarriage

Undercarriage Replacement Cost – $250.000

Average Life – 6,000 hours

Cost per Hour = $41.67 per hour

Inspected typically every 500 hours

(Note: None of these numbers above take into account the maintenance costs to keep the components achieving their budget life which really should be included in this calculation, but they will apply to both)

Undercarriage therefore is a far higher value component. Furthermore, the larger the machine, the higher the cost per hour of operation of the undercarriage. Does the undercarriage receive the same level of attention as the oil sample results?

How can undercarriage be better inspected and managed by companies owning and operating tracked machines?

To get further information and arrange a free demonstration simply fill in the form below.

[contact-form-7 id=”2772″]