Undercarriage inspection and management is more complicated than tyre management, yet is just as important; and in some cases more important. Undercarriage consists of more parts, which means more points of possible failure. Good management and regular inspection of these parts goes a long way towards mitigating this increased complexity.

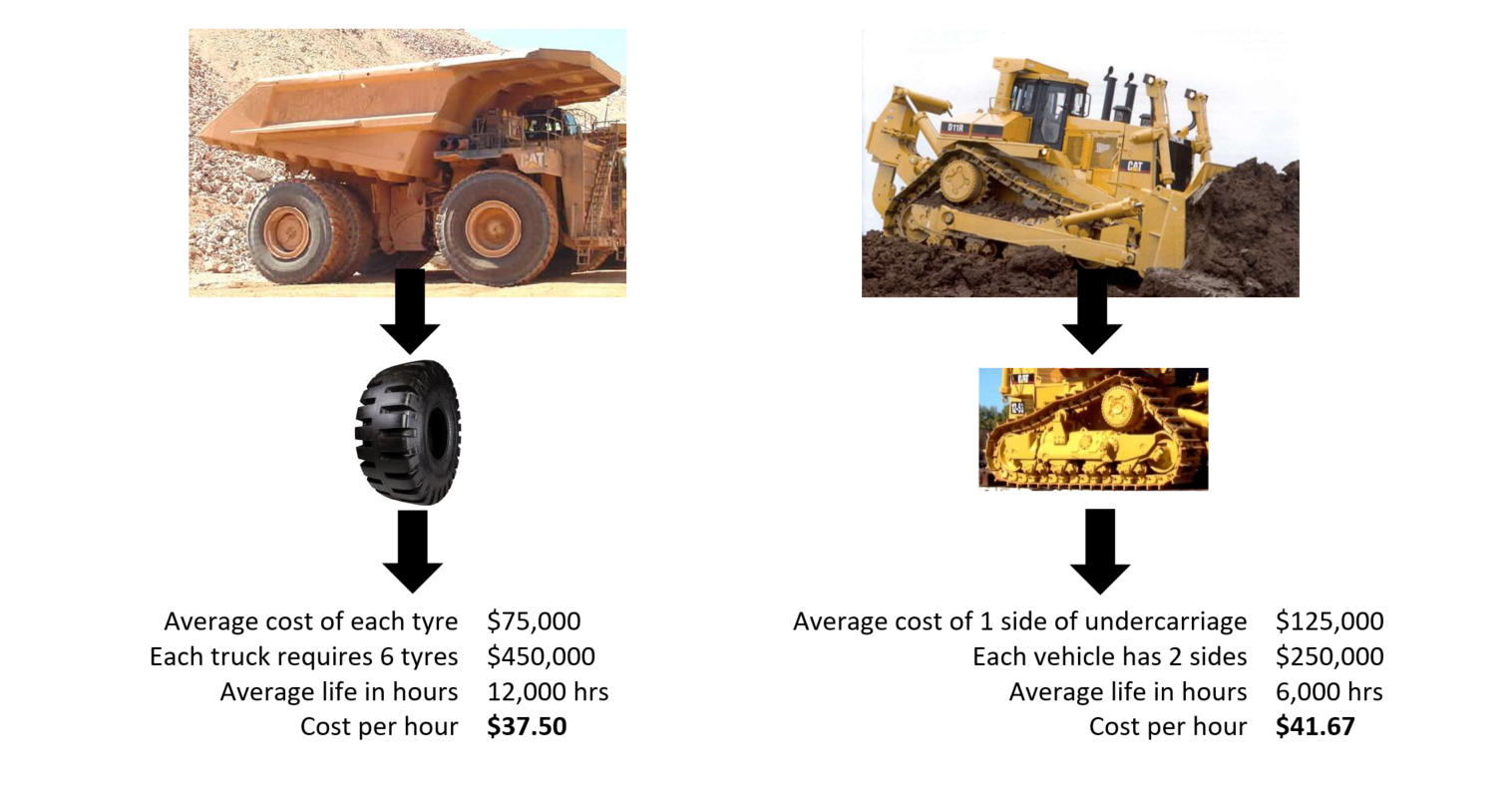

Looking at a cost comparison between Tyres on a 793 sized machine and the undercarriage on a D11 sized machine, the hourly costs are not that different. This however doesn’t factor in the costs associated with the increased possibility of downtime, due to component failure on the more complex shovel production machines.

Across even small fleets of undercarriage equipment, annual costs can quickly reach millions of dollars. Downtime due to undercarriage failure will dramatically increase this cost. Knowing in advance when maintenance needs to be carried out, allows you to schedule it in when it best suits you. Downtime costs money, unscheduled downtime costs even more.

Once we understand the relative cost per hour of undercarriage, we can then look at what is required to manage and achieve the best life from the total undercarriage system on each machine.

0 Comments