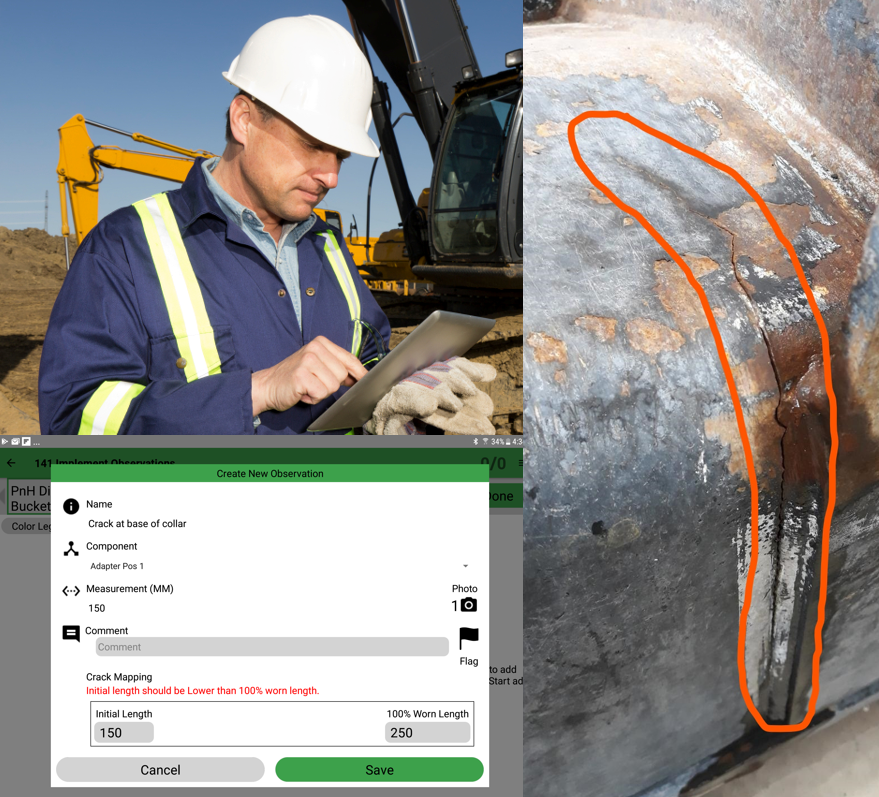

Step up to any tracked machine and inspect the undercarriage

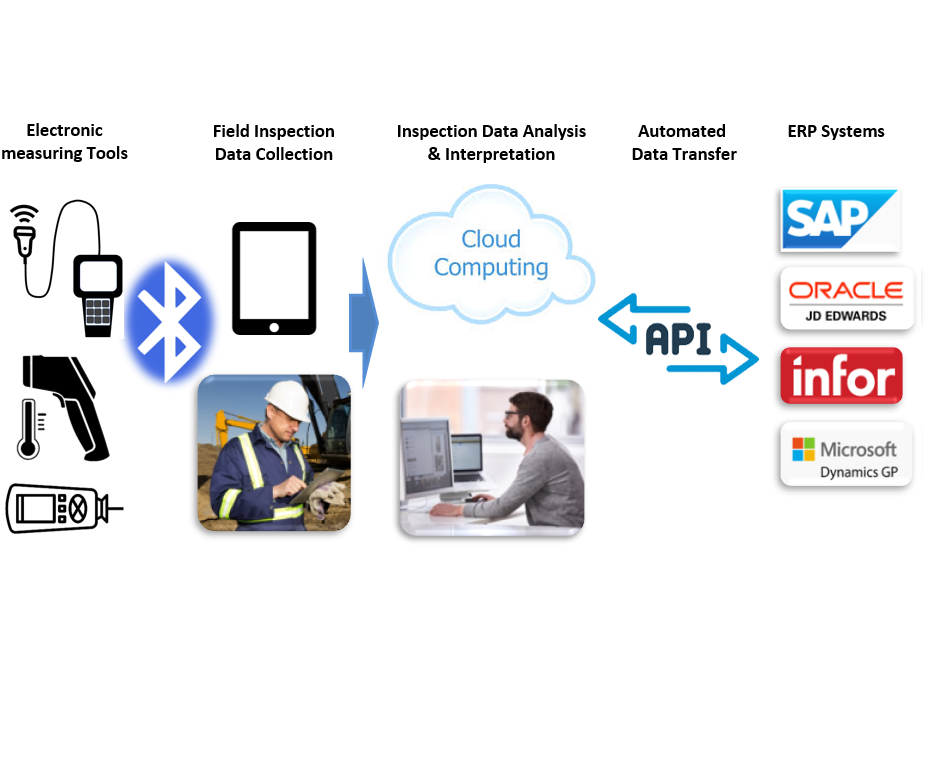

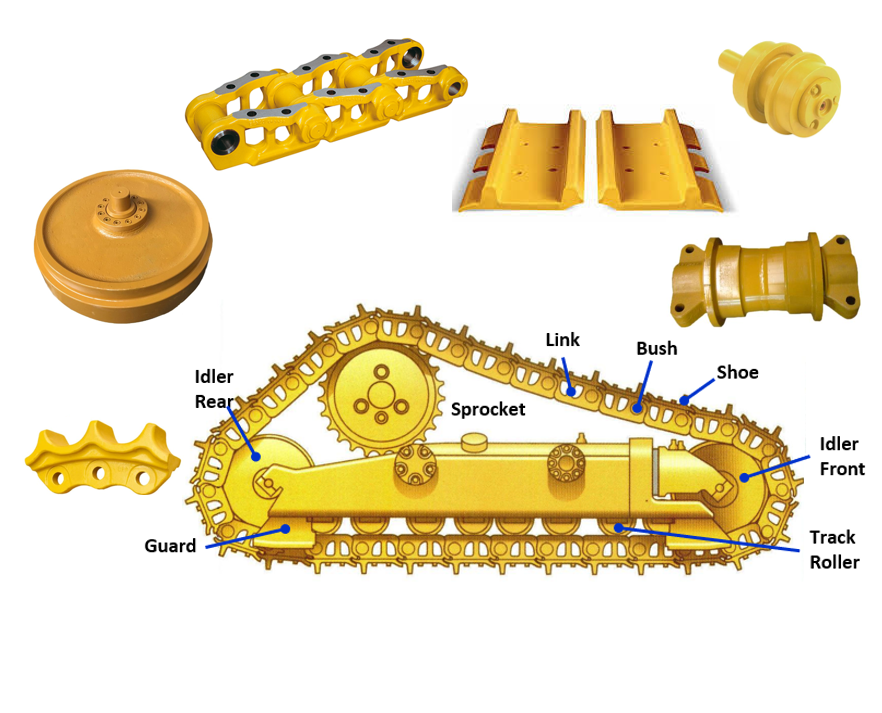

The TrackTreads Undercarriage system provides inspectors with a unique opportunity to inspect any brand of tracked machine and its undercarriage using the OEM wear limit specifications. This provides Fleet managers with 3 distinct unrivalled opportunities A single portal to view the condition of undercarriage across the fleet Enables Fleet managers to carry out inspections themselves […]

Step up to any tracked machine and inspect the undercarriage Read More »