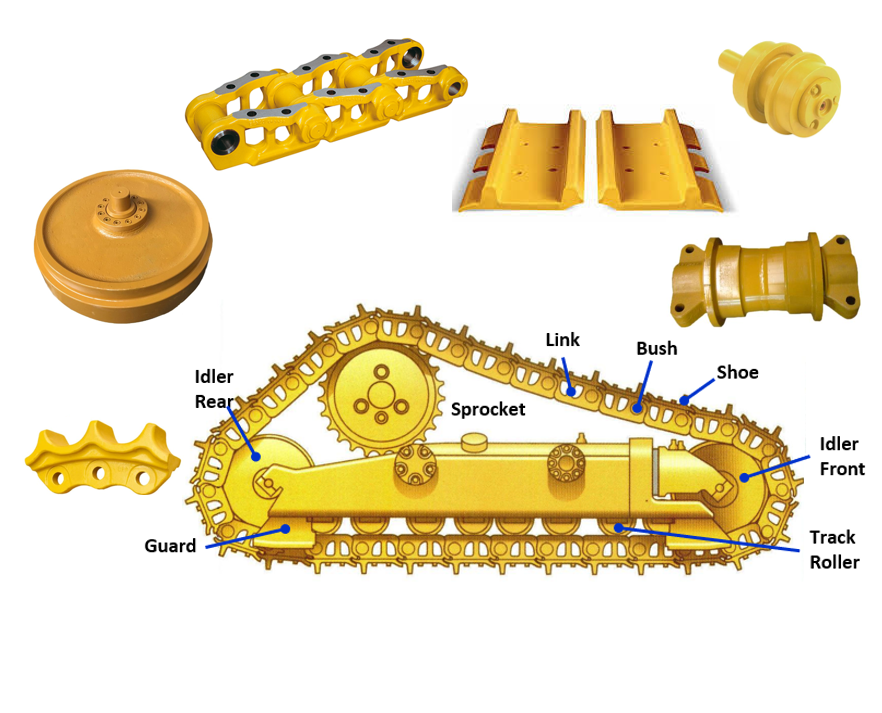

Undercarriage Management – What is the cost of doing nothing?

If you have a fleet of Heavy Equipment that includes Tracked Machines, there will be a line item on the income statement that includes the cost of replacement undercarriage components. The question would be, is that number fair and reasonable? Managing your undercarriage would be one way to determine if this number is fair Another […]

Undercarriage Management – What is the cost of doing nothing? Read More »