2 in 1 Bucket, Blade and Undercarriage Inspections in a single app saves time and money

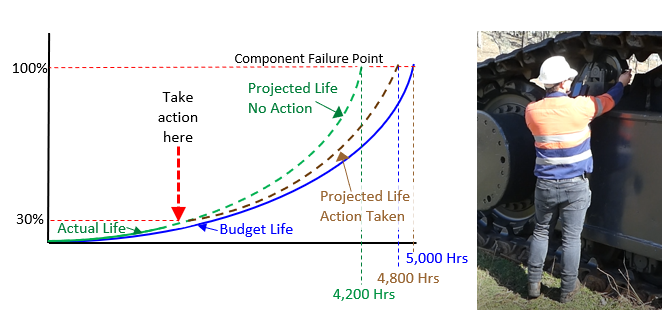

High Wear Components need to be monitored on any quarry or mine-site as they chew up heaps of money. Downtime for repairs or replacements needs to be planned while also monitoring the actual true performance of these components in cost per hour or tonne. This challenge has been made easier with TrackTreads 2 in 1 […]

2 in 1 Bucket, Blade and Undercarriage Inspections in a single app saves time and money Read More »