Reliability Engineers carry the burden of scheduling maintenance tasks to ensure maximum production availability of machinery with minimum downtime for maintenance. The quality of their decisions depending on the quality of the data available. Digitizing Field Inspections can provide more data, quicker and more accurately. It does not stop there

Digitizing Pre-starts, PM Services, Pre-Rentals and many other forms can save money in a number of ways: –

- Using a tablet to gather the information which is then synced to a web portal removes any transcription errors and requires no human labour time.

- Exceptions can be automatically flagged for follow-up thus reducing the need to re-check masses of forms to find issues for actioning.

- The system is a closed loop ensuring any items identified in the field are in some way closed out.

- Each question can include detail instructions with diagrams to ensure the question or task is completed correctly. The inspector can take images and comment to support his answered response in the field.

- Digitisation creates large volumes of accurate data in database format ready for analysis. This provides the Reliability Teams with a more reliable dataset for forecasting and decision making

- Images speak a thousand words and provide a perfect audit trail.

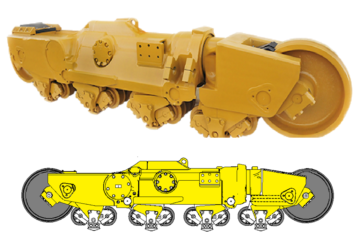

Digitized Inspection Check-sheets have been added to the TrackTreads system to expand the tools available for Field Inspection

0 Comments