Failed Undercarriage Frame components can cause untold damage to the undercarriage, reducing their life expectancy substantially. Any reduction in expected life increases the cost per hour.

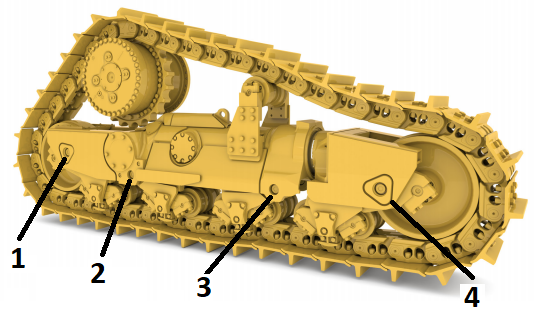

Looking at our first example in a series on frame components, is Major Bogie Pin failure or collapse. The bogie carries 2 track rollers in the minor bogie. There are 4 main bogies on each side of the track frame with the entire load of the machine being concentrated through the 8 track rollers on each side. A bogie pin collapse changes the dynamics of the operation of the Track Rollers substantially

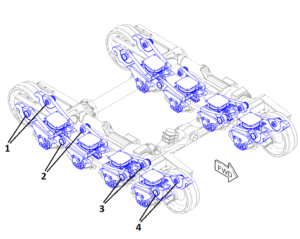

The Major Bogie Pins are marked in position 1 to 4 on the right-side Track Frame above. These pins are hidden by a cover plate (1 to 4) below, making examination possible only by the removal of the cover plate

A Major Bogie Pin Collapse or failure –

- Reduces the load bearing capacity of that bogie and shifts the load to the remaining track rollers thus increasing their wear rate

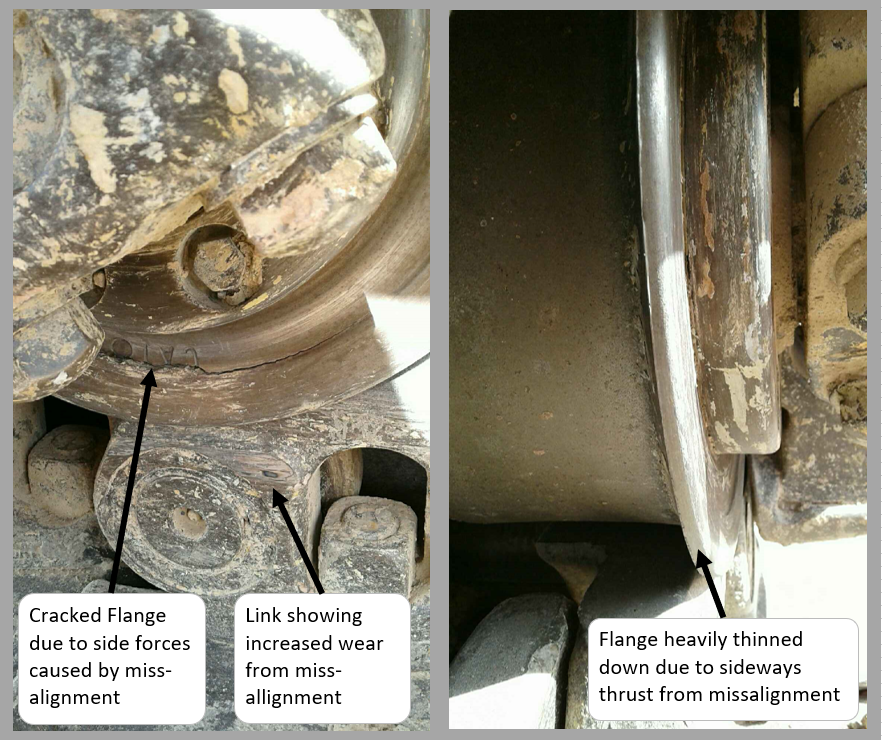

- causes accelerated wear on the track roller flanges of the affected bogie as the bogie is no longer aligned in the frame correctly

- Will also cause damage to the links, with the potential to prevent a Pin and Bush turn due to excessive pin wear or damage to the PPR groove on the outside of the link. This can cost huge dollars lost!

How is it possible to detect bogie pin failure and collapse?

- Elevated temperature of Bogie and rollers picked up in the Infrared imaging

- Loss of suspension detected by operator

- Uneven wear rates on the Track Rollers and increased wear rates

- Damage to the Track Roller flanges for the affected Bogie

- Clean metal wear on the side walls of the flanges of the affected bogie

- Clean metal wear/silver metal or metal deformation showing on the sides of the bogie where in contact with the undercarriage frame

- Jacking the machine during service to check for visible movement in the major bogie pins.

Undercarriage Inspectors need to be aware of these potential situations and the identifiers to avoid the machine operating under this condition. Viewing and touching the metal at an inspection and using thermal imaging are key to identifying these types of condition.

Monitoring your undercarriage through the TrackTreads Undercarriage System ensures you are not only able to identify these issues, but will be able to review the trend over history ensuring these problems are identified early.

If you have any questions or would like further information do not hesitate to contact us.