Scalloping is a dangerous condition leading to significant downstream costs if not identified early. So what is scalloping?

Scalloping of the links is where the midsection of the link becomes hollowed out.

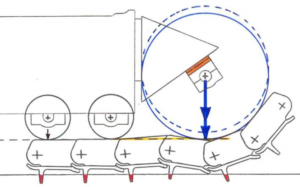

As the hollowed-out link /rail passes over each roller and idler, it creates vibration. The larger the scalloping, the greater the vibration. This will create health issues for the operator and cause secondary damage to the machine. The vibration and impact also accelerates the wear on the Track Rollers, Idlers and the links. Secondary areas being damaged are the cracking of undercarriage frames, chassis and increased wear on final drive bearings, among others.

Cause of Scalloping

So a major cause of scalloping in elevated sprocket machines is where the idler rise height is in-sufficient to ensure that the idler contact with the rail is higher than the level of the Track Rollers. This causes the grouser directly under the idler to be lower than the grouser bars under the rear Track Rollers. This causes the link to start wrapping around the Idler and creating the scallop wear profile. More importantly the load of the machine is concentrated on the link through the idler rather than distributing the load across the track rollers.

Note, the idler is not supposed to place a vertical load on the links.

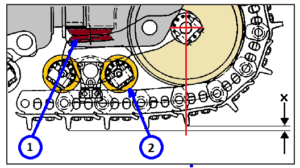

The main causes of Idler Rise height (shown as X in the following diagram) being in-sufficent is:-

- Worn bogie pads

- Worn Track Rollers

But regular inspection of the undercarriage will indicate scalloping beginning to occur. Measuring the Track Roller wear and inspecting the Bogie pads as part of the undercarriage inspection will ensure that the signs leading to early scalloping will be identified before it becomes a problem.

Monitoring your undercarriage through the TrackTreads Undercarriage System ensures you are not only able to identify these issues, but will be able to review the trend over history ensuring these problems are identified early.

If you have any questions or would like further information do not hesitate to contact us.