TrackTreads

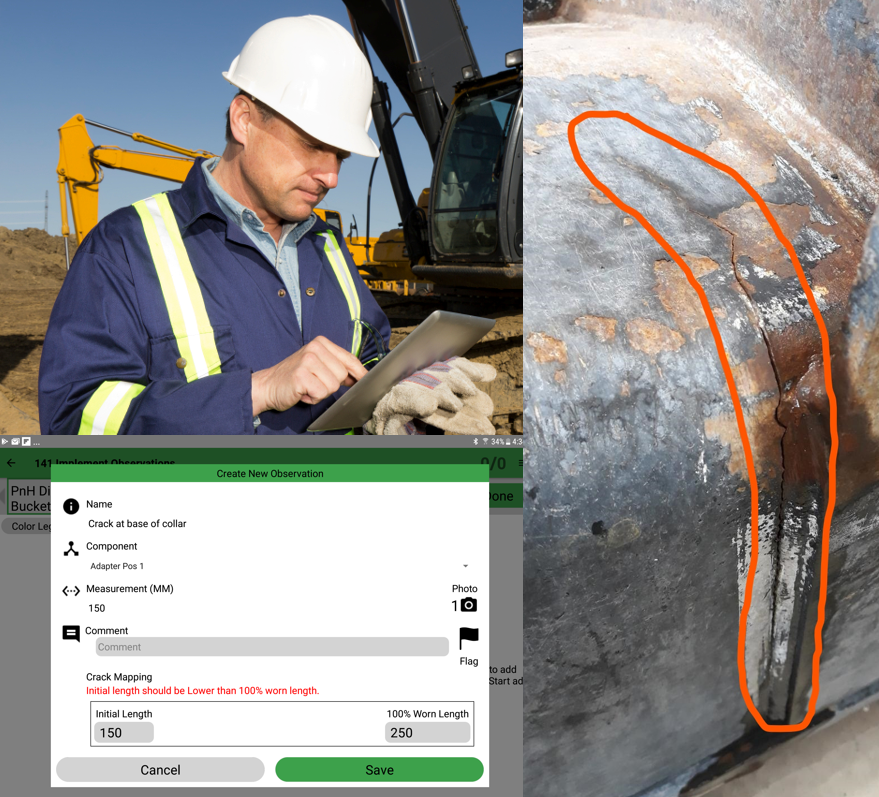

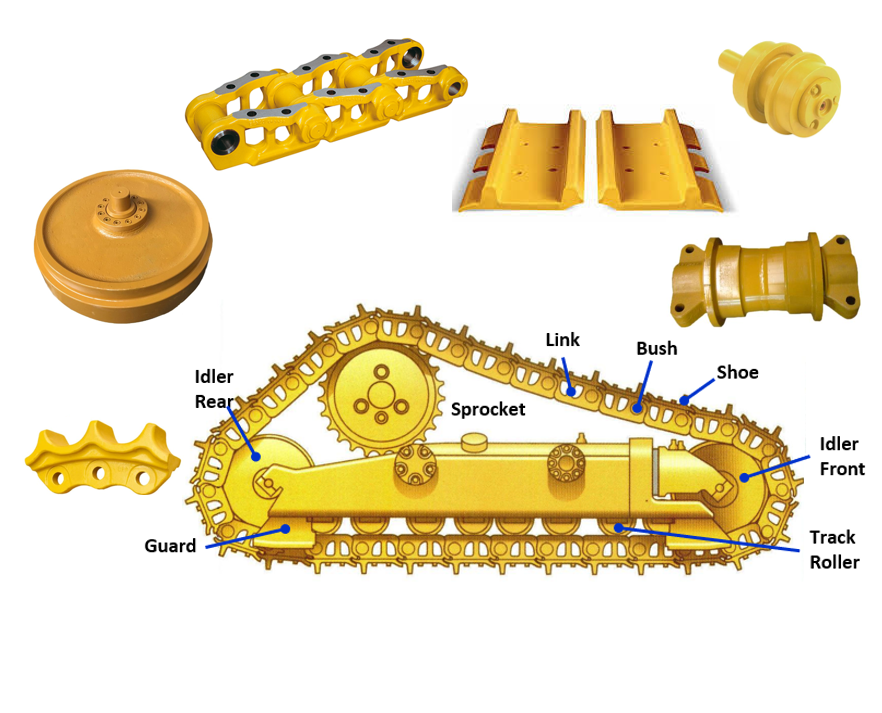

Inspectors can walk up to any tracked machine and measure the Undercarriage

Every fleet owner of earth moving machinery has multiple different makes and models of machines. Machines are acquired to match their strengths to the specific requirements of the project and ensure cost effectiveness. This does of course create a headache for the customer when it comes to measuring the undercarriage. Read more…