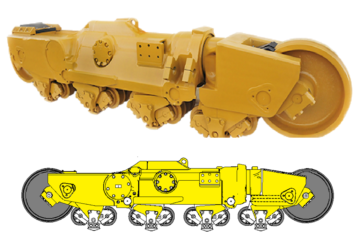

Undercarriage Shoes provide flotation for the tracked machine on soft ground. The grouser bars provide the grip to enable to machine to propel forward. The grouser bar also provides a secondary function by adding structural strength to the shoe, the more grouser bars, the greater the shoe strength and the more loading the shoe can withstand.

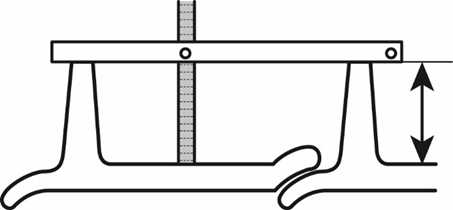

Shoes can be measured using a depth Gauge or the Ultra Sonic Tool. The grouser bar often becomes rounded on the ends, so the measurement should be taken at least a third of the way across the grouser bar

The Depth Gauge will measure effectively the height of the grouser bar, but not the plate thickness

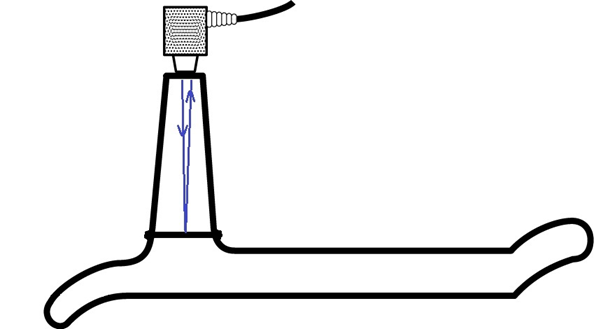

While the UT will measure both the height of the grouser bar and the plate thickness

If the shoe has been re-barred/re-groused, the Ultra Sonic Tool is no longer an option. This is because the signal is interrupted at the point at which the bar has been welded.

Issues to be on the lookout for when Inspecting Shoes

- Grouser Bar end wear – this could indicate frequent turning or rough underfoot conditions. Wearing the grouser bar down, will cause loss of traction and reduce the overall strength of the shoe

- Plate Wear – this can be caused in highly abrasive conditions and will lead to loss of plate strength and then bending of the plate/shoe. Where the trailing edges of the plate are worn, this can lead to the plate bending and then interference with the adjacent plates and damage.

- Plate Corner & Grouser Ends breakage – this can happy in high impact conditions and will cause the loss of strength in the plate and thus increases the loading on adjacent plates.

Cracks through plate and Grouser – cracks will occur due to high impact conditions or plates/shoes being too wide for the application. This will cause shoe failure, increasing the load on adjacent shoes. Check whether cracks emanate for bolt holes or self-cleaning holes. Bolts could be

Contact us today if you are looking for a software solution to manage your undercarriage inspection data, or you need training on how to perform undercarriage Audits. We are here to help.

0 Comments