Undercarriage Bush Turns can save money

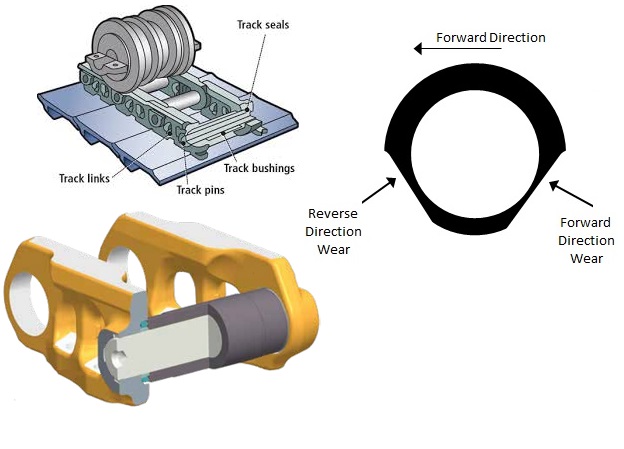

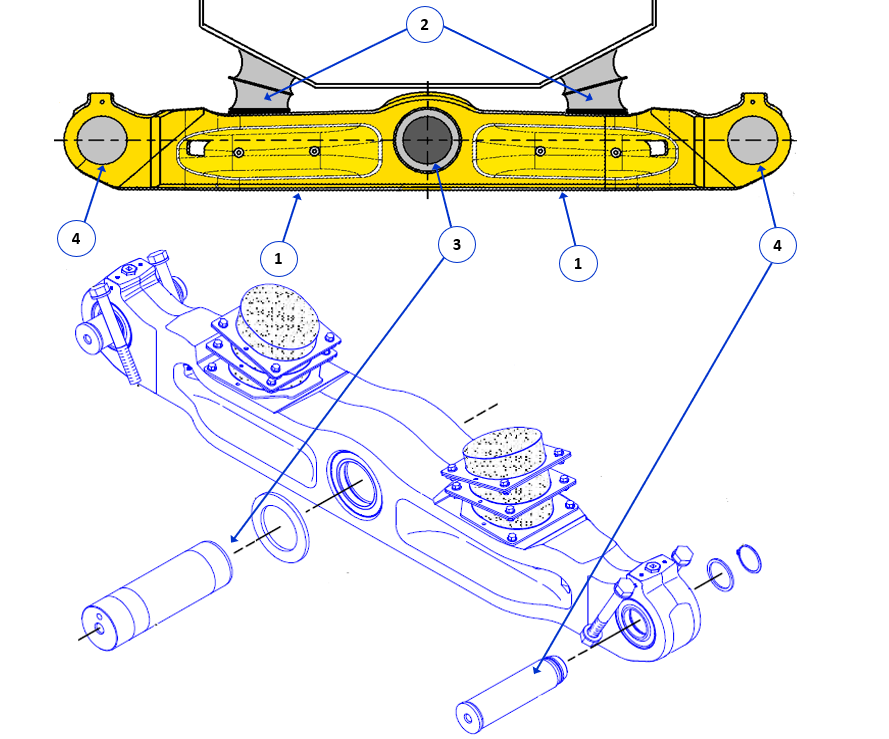

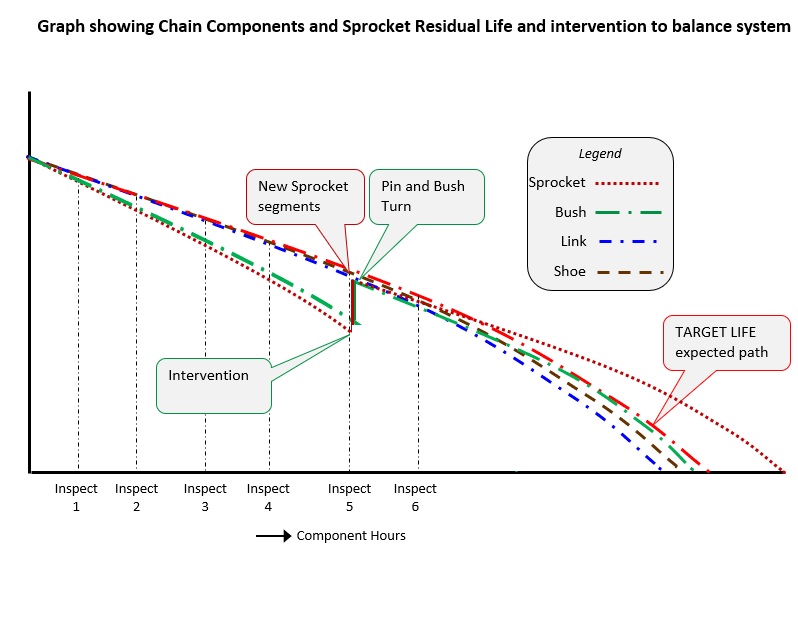

Managing Undercarriage Bush Turns to save money requires skill, inspection data and systems to accumulate the data. Under Covid-19 conditions, many companies operating tracked fleets may need to manage this in-house, since supplier inspectors are not currently able to visit the machines. Technology can now provide solutions to this challenge. Looking at Bush wear, the […]

Undercarriage Bush Turns can save money Read More »