A Focus On Reducing Cost Per Hour

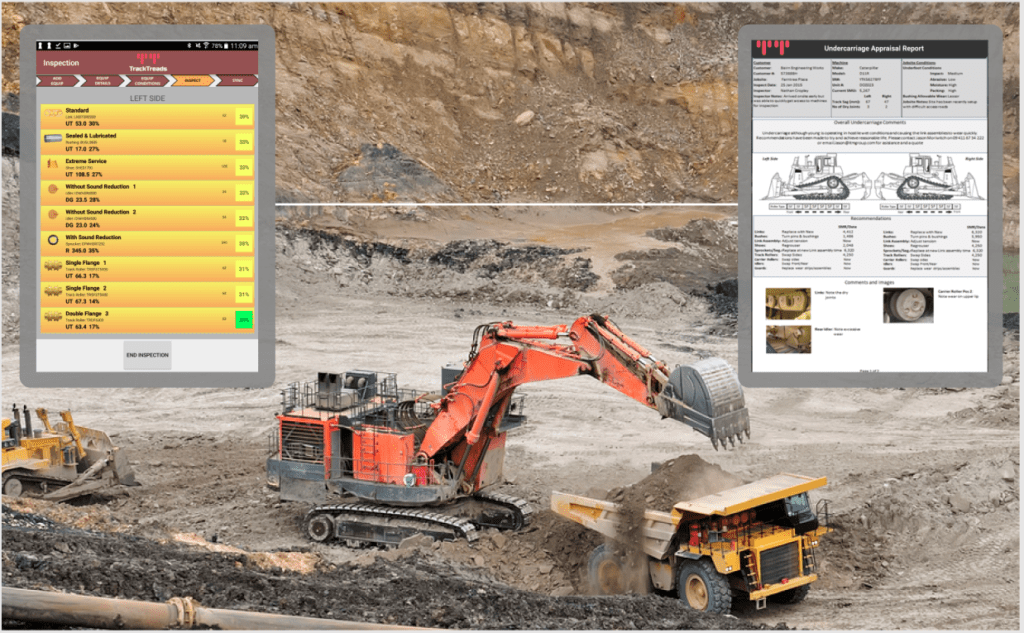

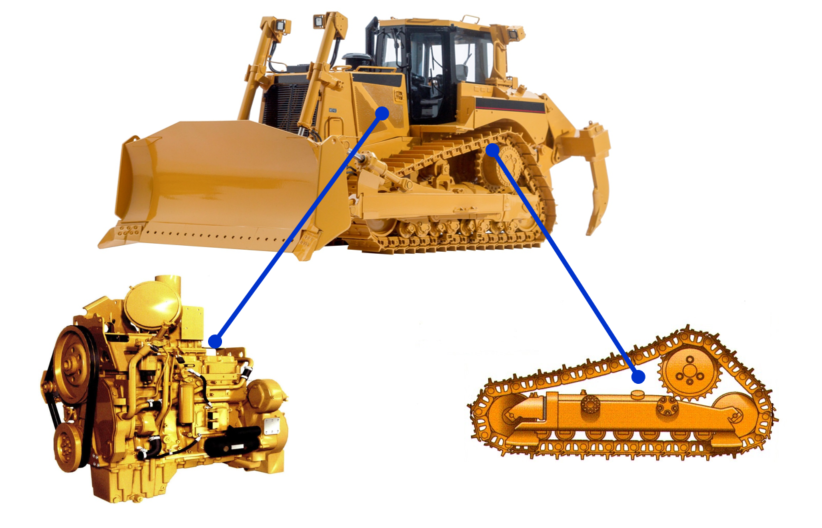

In reposonse to high demand from many mining customers TrackTreads has now incorporated GET, Dump Bodies and other wear surface management tools into the same package and offering as the Undercarriage solution. This gives inspectors the ability to inspect the following wear surfaces; undercarriage, dozer and grader blades, excavator and shovel buckets, dipper buckets, […]

A Focus On Reducing Cost Per Hour Read More »