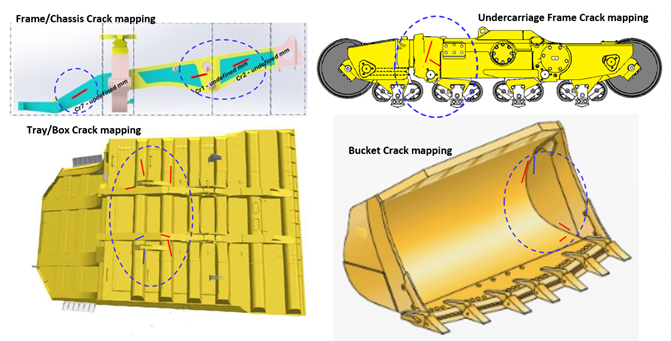

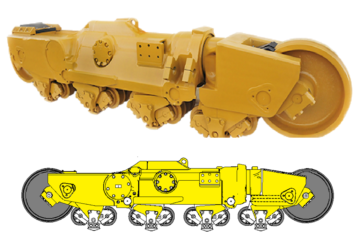

The TrackTreads system provides “cradle to grave” Crack Management in Mobile Fleet Structures.

There are 4 main steps covered in the management of these cracks

- Identification, measurement and setting of limits

Field Inspectors capture, using mobile phones or tablets, the precise position of the crack on the structure by drawing the crack on a structural schematic displayed on the mobile screen. The length, severity, images, and comments are added along with possibly a flag alert to draw the supervisor’s attention. The maximum crack length can be entered to enable forecasting.

- Monitoring crack growth rate

If the crack is not immediately repaired, its propagation/growth rate can be monitored during successive inspections and measurement of crack length and condition in the field. This is also compared with the maximum crack length to determine drop dead fix date

- Repair Work defined and Scheduled

The cracks can be repaired immediately or scheduled for repair at the next service intervention based on the severity of the crack and its position on the component. Data provided on the work order can include: Component affected, precise position on component shown on schematic, length of crack, images and comments

- Completion of Repairs

The crack will be gouged and welded, its status changed to “Fixed” with costs and date recorded for the audit trail. All fixed cracks can be viewed historically with different colours on the schematic to enable viewing of where cracks have historically occurred.

Contact us at TrackTreads.com to trial this functionality on your jobsite

0 Comments