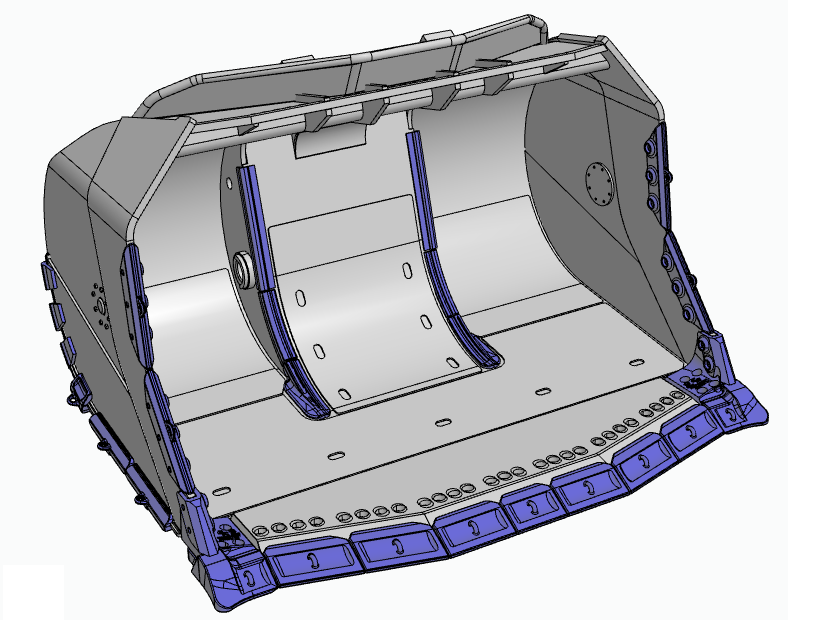

Inspectors can now perform condition and wear measurement inspections underground on their mobile device on GET, Wear Plates, the bucket core and attachment points for their underground buckets.

The system will automatically forecast when the bucket needs rebuilding based on the wear percentage and residual life of the critical components, while also displaying performance against a preset budget life.

The system will capture the cost of replacement components for GET, and Wear Material, along with the Tons or BCM moved allowing a Cost per Hour, Cost per Ton or Cost per BCM to automatically be calculated.

At the end of each buckets life cycle, the bucket can be rebuilt, and a new life commenced, with all performance data being kept for each life

Contact TrackTreads at Help@TrackTreads.com if you would like to commence monitoring your underground buckets from today.

You may also be interested in:

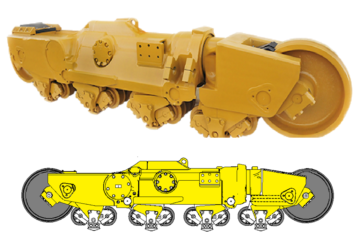

Undercarriage Inspection Management: a complete tool to inspect and manage the inspection results of undercarriage on any make or model of machine from small rubber tracked excavators up to the largest Hydraulic Face Shovels, Rope Shovels and all types of dozers.

Shovel Bucket Management: a complete tool to manage backhoe and Face Shovel buckets including core of the bucket, wear plates and GET. System tracks changeouts, BCM/Tonnes moved, costs incurred and many more to provide a complete set of performance data for each bucket across its life cycle. System predicts the future Date for bucket rebuild based on percentage wear of critical components.

Major Component Rebuild Audit: this is a complete tool for tracking the rebuilding of Undercarriage Track frame components recording all measurements, cracks, images and components of each subcomponent detail. The detail is then displayed in a report provided to the customer to support the detailed costing of the rebuild.

0 Comments