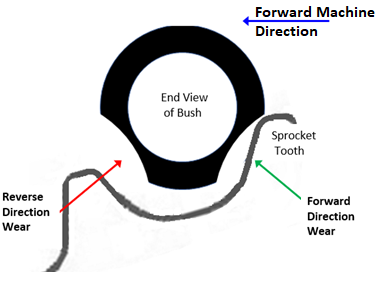

Ensure Chain is Installed in correct Direction to avoid quick destruction

Undercarriage Chain is built to operate in a specific direction of motion, this is the forward direction in which the machine operates under load. When the chain is installed in the incorrect direction, the reverse direction, will cause wear at 3 times the rate of the forward direction. It is thus critically important to […]

Ensure Chain is Installed in correct Direction to avoid quick destruction Read More »