Undercarriage Inventory Management

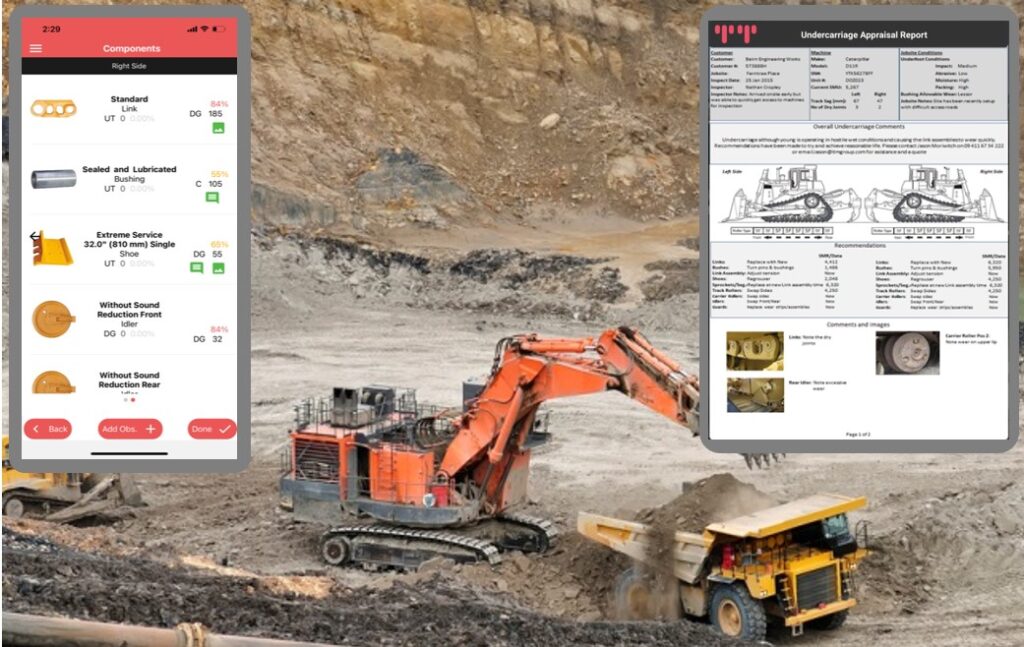

Ensure dozer swing chains and frames are available when required so teams can remove and rebuild installed components without impacting production. Effective inventory management keeps components ready, tracked, and rebuilds on schedule. This results in end to end swing chain and Frame inventory management. Key Capabilities Immediate Benefits TrackTreads provides the Software Tools to manage […]

Undercarriage Inventory Management Read More »