Undercarriage Management – Increasing Your ROI

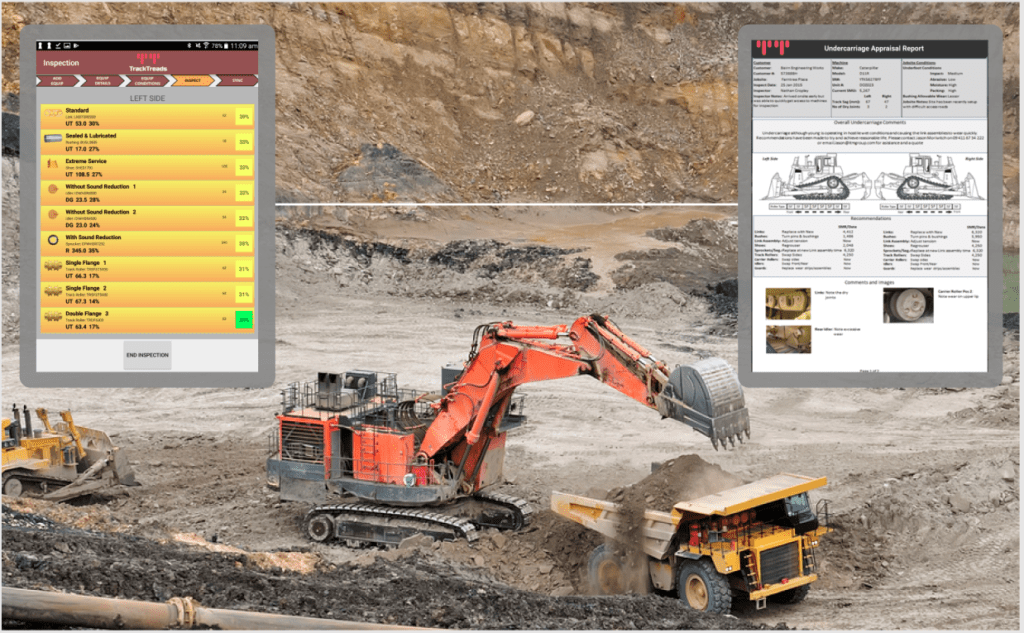

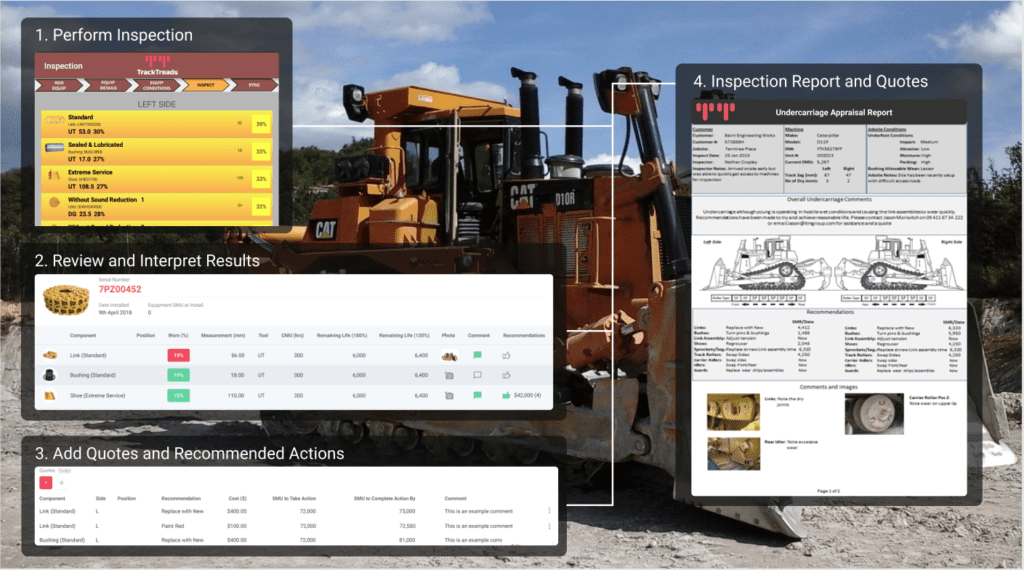

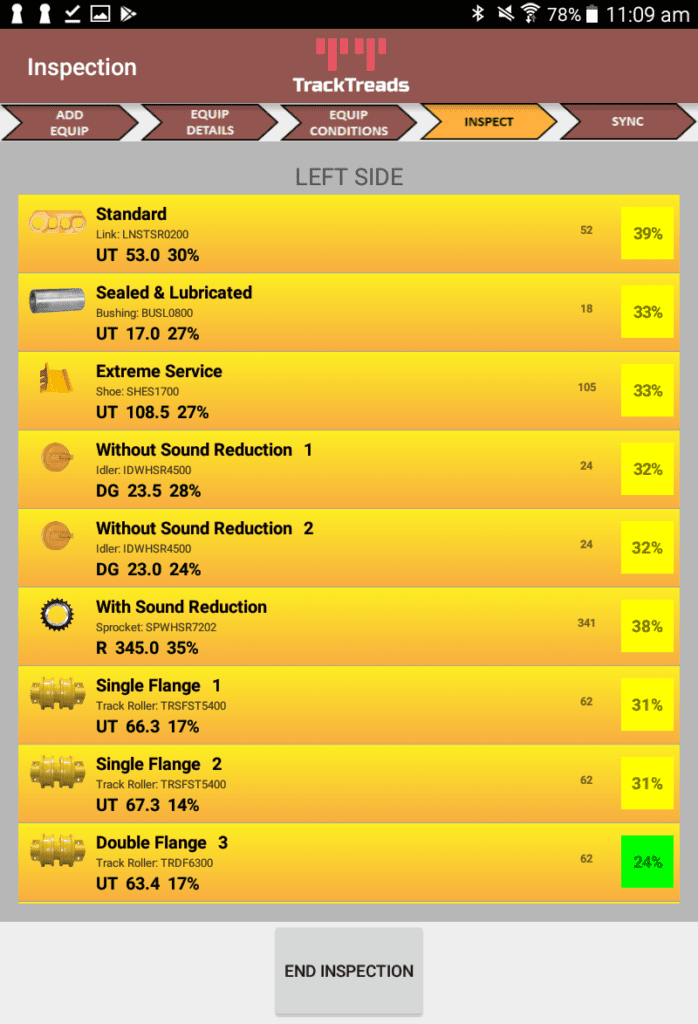

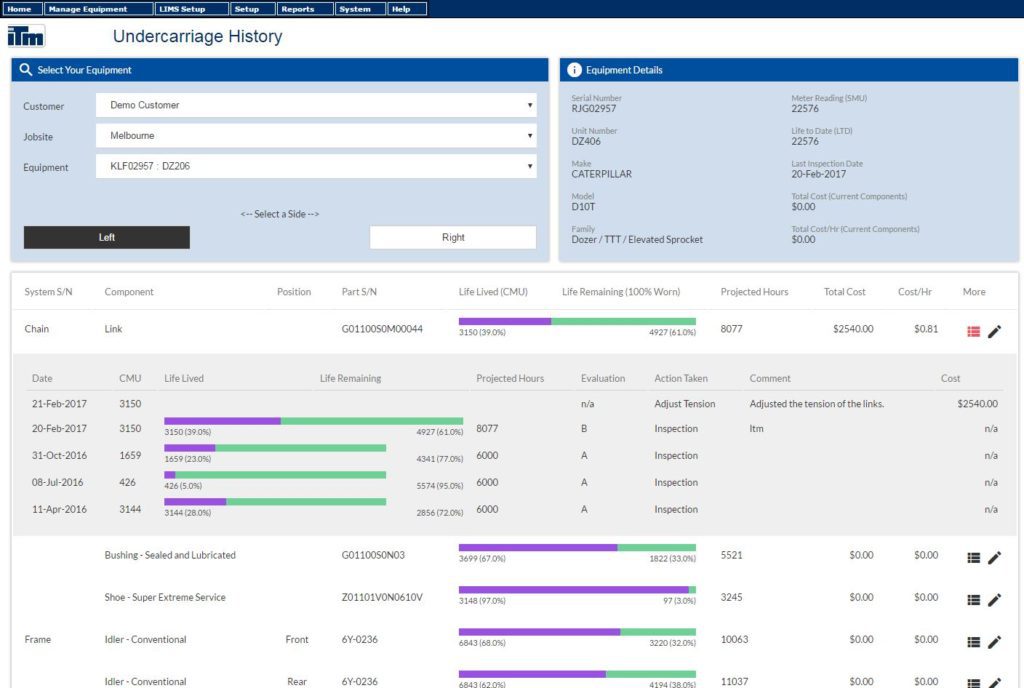

Investing in the implementation and use of undercarriage inspection management software needs to provide a return on investment. Undercarriage can make up more than 50% of the maintenance costs of a machine. Therefore managing undercarriage has the potential for large savings. How is the ROI measured:- Time and accuracy to complete an inspection The […]

Undercarriage Management – Increasing Your ROI Read More »