Undercarriage Training Workshops – a forum for increasing knowledge and know how

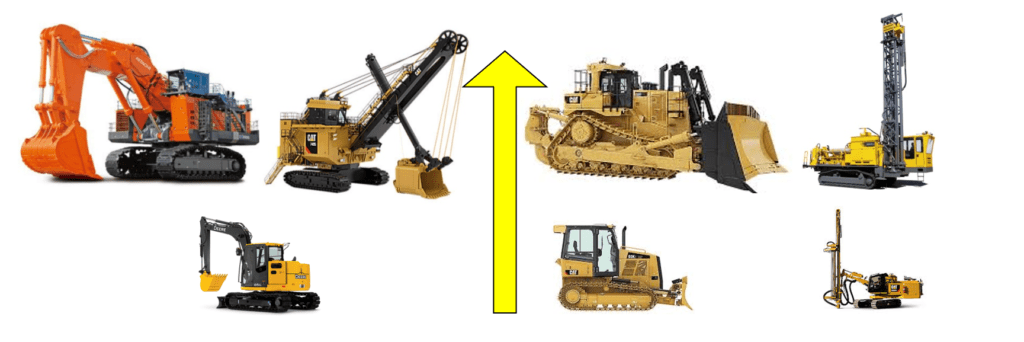

All subjects are a mystery until studied in more detail. The more the subject is studied, discussed and experienced, the greater the number of subject matter experts. On a typical mine site, you will find many different subject matter experts, Tire experts, Planning experts, Drilling and Blasting experts, Operations experts and so on. Among all […]

Undercarriage Training Workshops – a forum for increasing knowledge and know how Read More »