Undercarriage Idler Failure can be detected to avoid further Damage and Expense

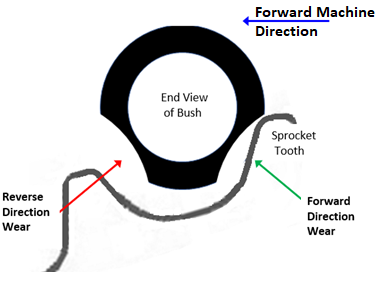

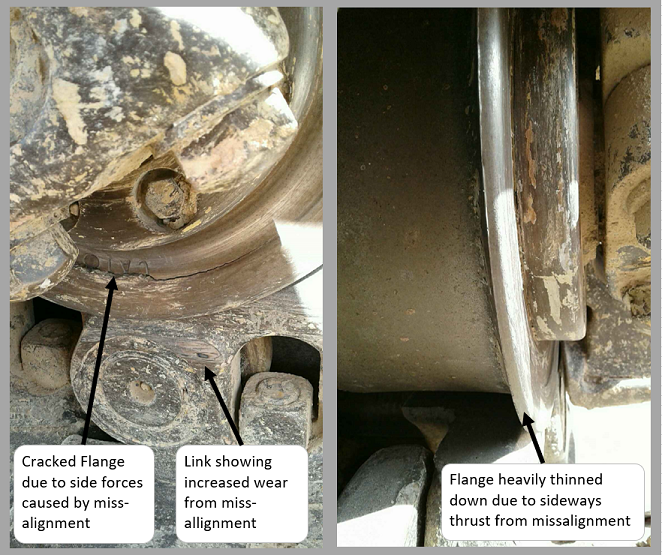

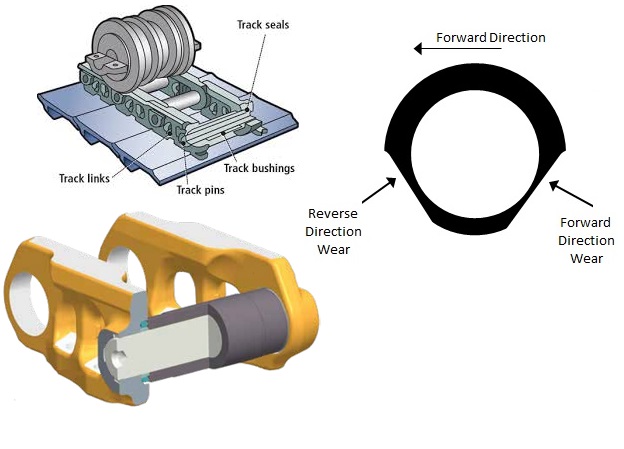

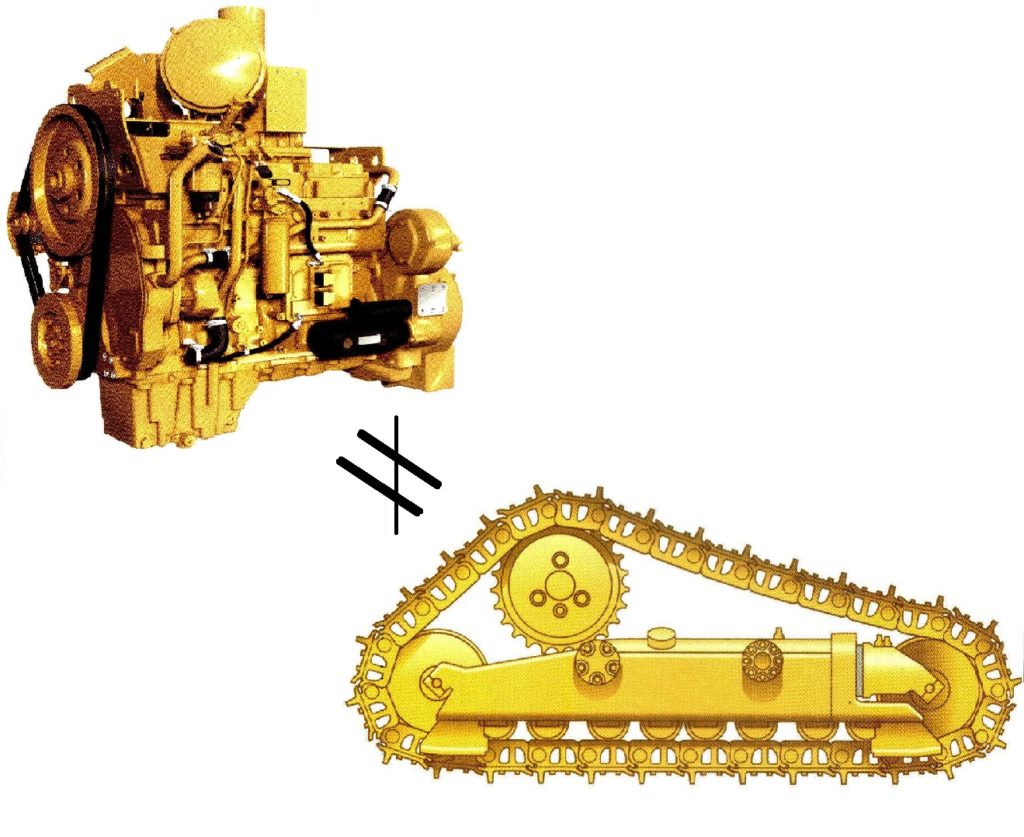

The Front and Rear Idlers on an elevated sprocket machine are effectively the spreaders for the track chain. The idlers keep the chain reasonably tensioned and guides the chain as it rotates. The track chain is essentially a rail that is laid down and picked up again in a continuous movement that allows the machine […]

Undercarriage Idler Failure can be detected to avoid further Damage and Expense Read More »