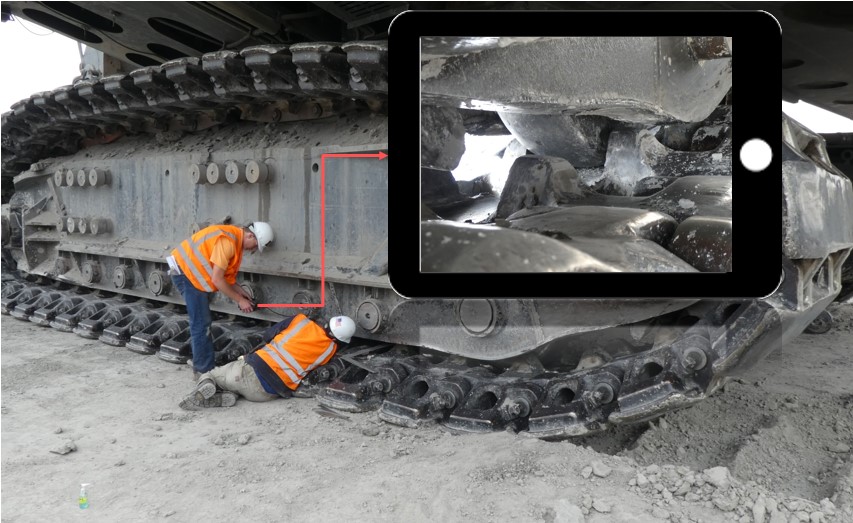

Quoting and tracking the progress of large component rebuilds made easier with TrackTreads CRC software

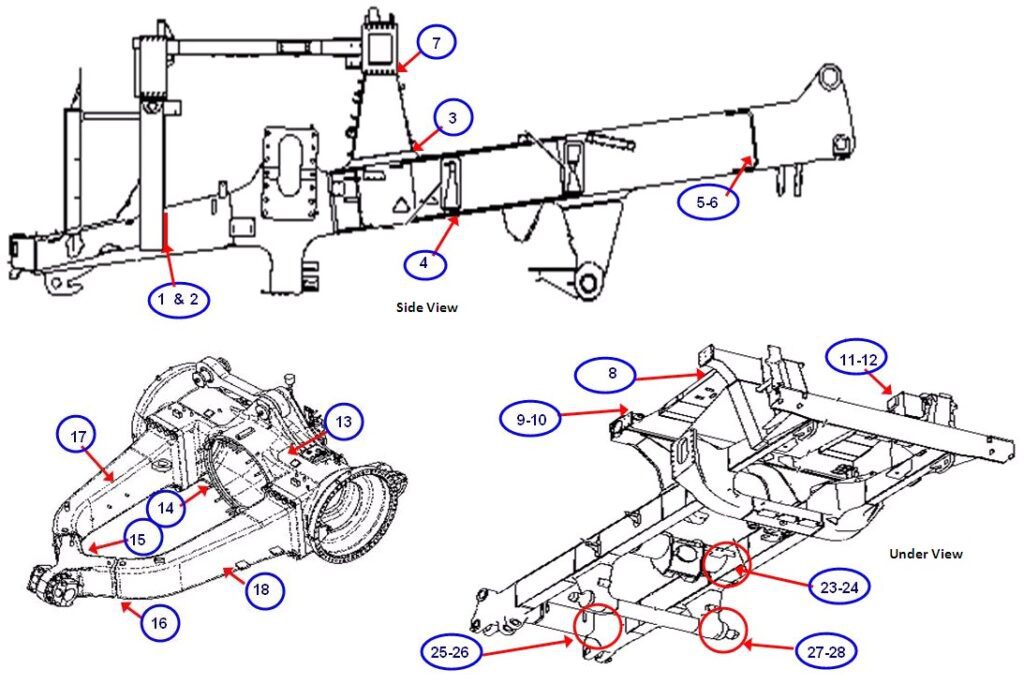

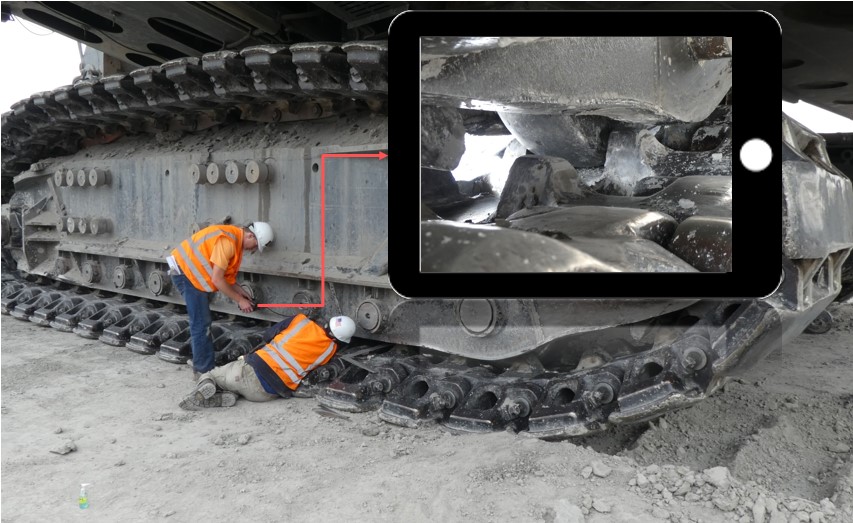

TrackTreads Component Rebuild Centre software system focusses on tracking the detail of the rebuild at granular level to ensure a complete audit trail and accurate costing for any large component rebuild: – During the disassembly process, each observation points condition is analysed through inspection. This could be diminished material thickness due to wear and tear, […]