Achieve Maximum ROI on your undercarriage for Tracked Machines

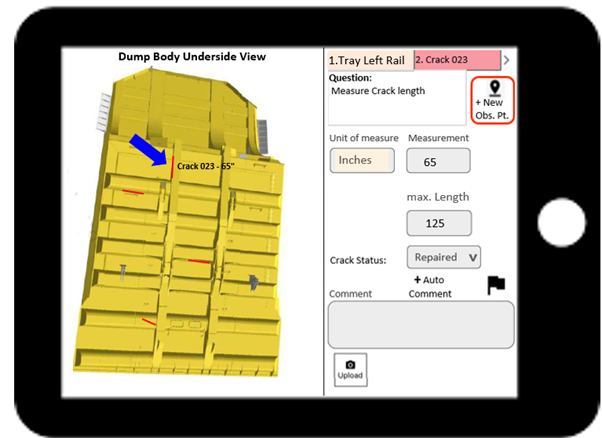

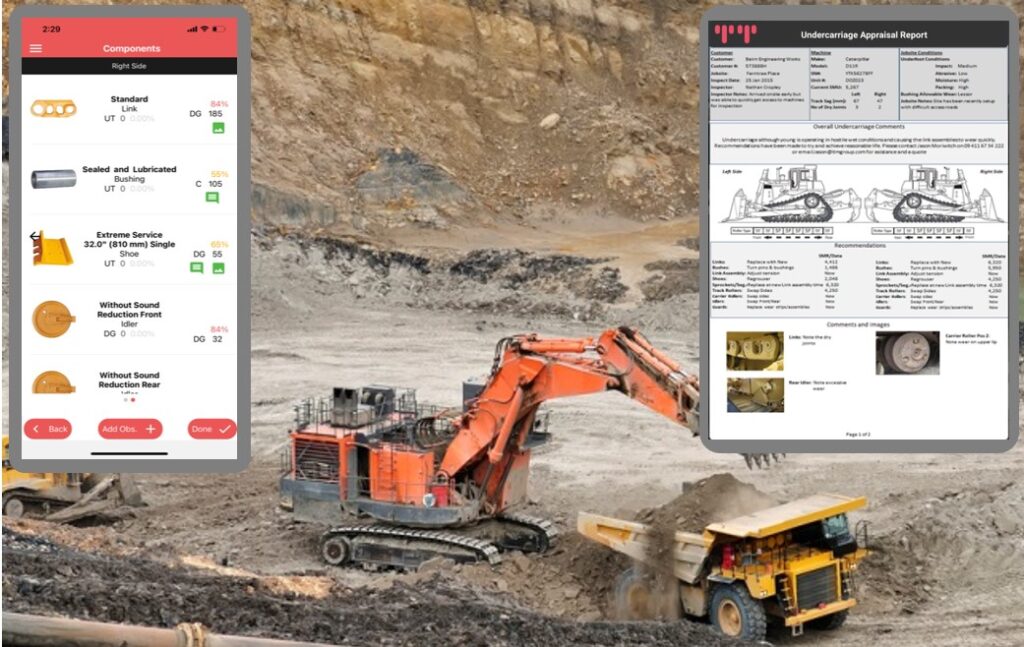

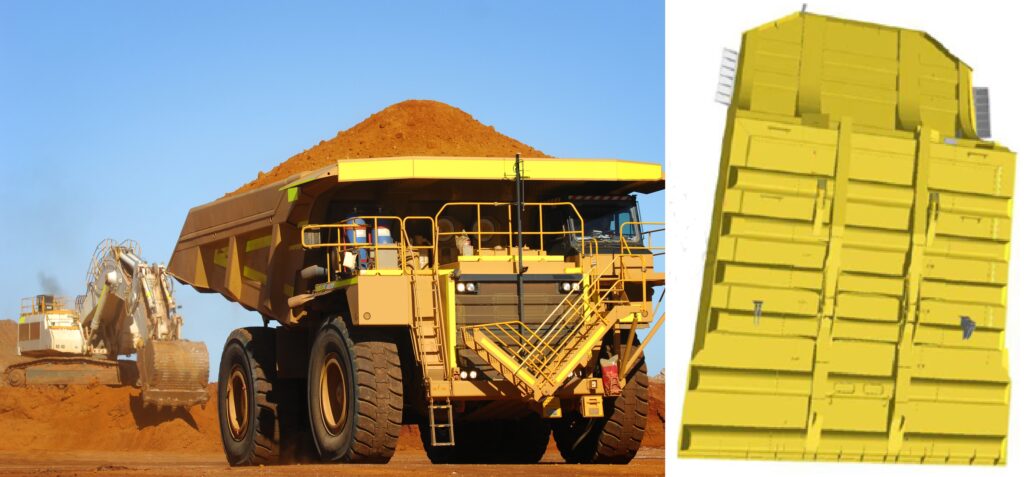

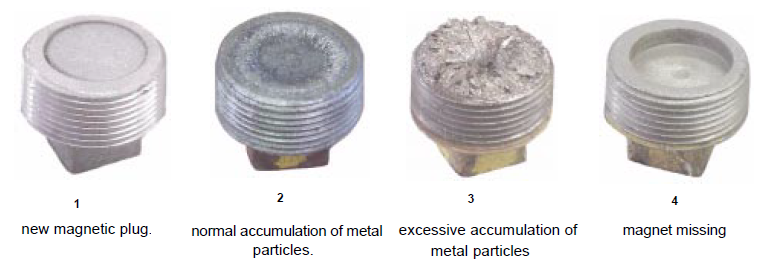

Increasing return on your undercarriage requires implementing and then maintaining certain basic steps as part of the normal business process. These steps require discipline but are simple to implement. Regular Track Inspections Undercarriage inspections should be performed regularly to measure components, calculate the amount of wear on each component, take images and observe the condition […]

Achieve Maximum ROI on your undercarriage for Tracked Machines Read More »