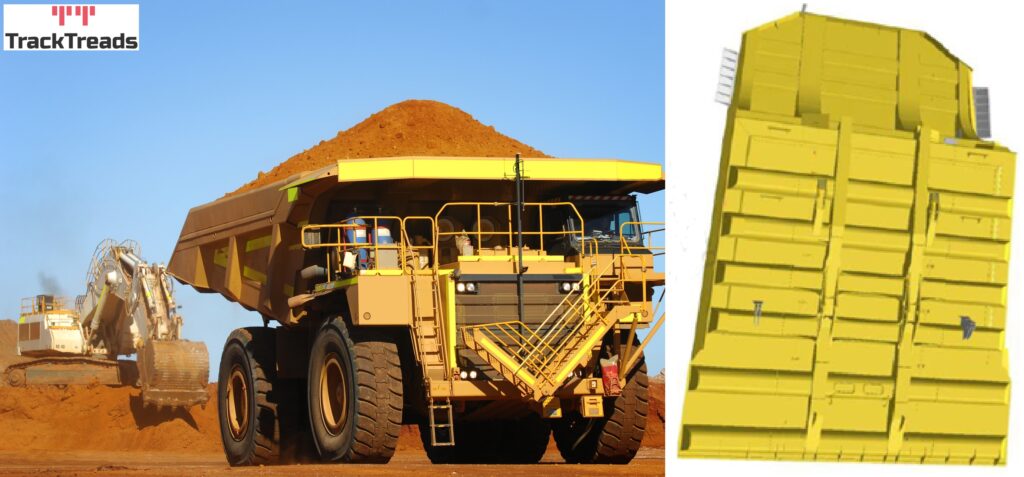

Dump bodies on Off-Highway trucks are a typical component subject to wear rates based on the material being loaded. High wear areas may use sacrificial wear plates or GET for extra protection. Heavy loads can cause flexing of the body with resultant cracking.

To track the life and performance of the dump body, we start by breaking down the life cycles. The first cycle commences with the building and installation of a new dump body onto a truck. Each life cycle has an expectation of budget hours it should achieve. The actual hours achieved is then tracked against this budget expectation. The actual hours on the dump body being dependent on the condition, wear, damage and cracking. The condition can only be determined through physical inspection, probably every 1000 Hours

Each inspection will look at different aspects of the dump body and will be captured digitally using mobile phone or tablet and includes images, comments, observation and measurements.

- Core underlying body condition, cracks, damage, worn through.

- Amount of wear on sacrificial wear plates, GET and core. All thicknesses measured using an Ultrasonic Tool

- Signs of cracking on the bolsters and any other areas. Crack lengths will be captured and thenceforth monitored. They may be welded or identified for welding at next service based on severity and length. All crack positions are monitored recording the point in hours at which they were identified and the specific position on the dump body. This can then be tracked across the fleet to identify if there are any patterns.

- Side wall damage due to rock and bucket strikes

- Condition of attachment points with chassis and lift cylinders, bush and pin condition.

All the data from the inspection is synced with the cloud database to enable the reliability engineers to schedule and plan the repair actions. Trends can then also be identified and monitored across the fleet over time.

Dump Bodies will eventually reach a point that they will need to be removed from the truck and rebuilt.

- Various sections of the body will be replaced,

- Sacrificial wear plates and GET removed and replaced,

- Cracks will be welded

All costs associated with the work will be recorded and tracked and the dump body commences a new cycle

Once back onsite, whether rebuild is completed onsite or offsite, it is ready to commence another life on any of the available trucks.

The entire process is captured and recorded for each and every dump body to provide a complete picture of the Dump Bodies life events and performance compared against all the other dump bodies in the fleet.

Managing Dump Bodie in this way has many benefits

- Digitized inspections provide fleet dump body condition at a glance

- Inspection data can be collected quickly and easily without any transcription

- Collection of data using mobile phones increases safety of inspectors at heights.

- Ultrasonic Tool measurements provide accurate thickness measurements

- Inspection data provides data for planning and scheduling and repairs

- Improved planning of repairs leads to greater efficiency, less downtime, and less catastrophic failures

- Early identification of problems in the tray’s lifecycle ensures repairs are completed before it becomes a large problem and cost.

- Crack history provides a forecast tool for identifying future cracks at specific intervals on the dump body

- Electronic Inspection and repair data creates a full auditable trail and ensures nothing is missed

- All data collected creates a data set to analyze performance and cost per hour expectation

0 Comments